What is it that makes a fire in the fireplace such a warm, welcoming experience?

So, what exactly is radiant heat?

Radiant heat is invisible, extremely intense, electromagnetic waves that travel at the speed of light with little resistance from air. When these waves strike an object they are absorbed and their energy is converted to heat. If the object is a combustible material, such as paper, fabric, or wood, a fire will start when the material’s ignition temperature is reached. Radiant heat is extremely dangerous to building occupants since it can quickly reach a level that causes unbearable pain, followed rapidly by second degree burns, preventing safe egress.

Why should you be concerned about radiant heat transfer?

Each year lives and property are destroyed by fire -- destruction that could be avoided, or certainly minimized, by applying what we know about fire and fire protection. For example, structures that survived the Oakland/Berkeley Hills fire in 1991, which killed 25 people, injured 150 and destroyed more than 3,000 buildings, had several things in common. In addition to having fire-resistive roofing material; large, clear yards; stucco exterior walls; and few overhangs, they had windows that resisted breakage in the face of fire and reduced the transfer of radiant heat. These windows protected a structure’s interior from even the highest heat levels.

In order to determine the safe use of fire-rated glazing in critical life safety locations, you need to know how much radiated energy passes through any given fire-rated glass product. Often this task is left to the architect or contractor who must figure out a structure’s radiant heat hazards and safe distances before choosing the appropriate product based on listings, which do not always provide sufficient information. To minimize the inevitable confusion, it is helpful to remember that U.S. building codes, recognizing the dangers of radiant heat, do not recognize the use of non-temperature rise window applications over 45 minutes.

Where should you be concerned about radiant heat?

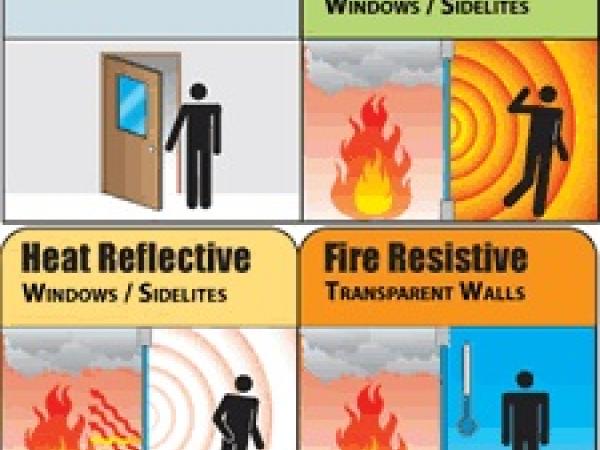

You should be concerned about radiant heat transfer in locations where the objective is to protect lives or property, where uncontrolled radiant heat can impact occupants needing to exit past glass and where the potential for fire spread due to auto-ignition of combustibles is a possibility. Of particular consideration is the speed with which occupants can pass by the glazing, the width of the corridor, and the amount of fuel on the other side of the glazing.

Radiant heat is typically measured on the non-fire side at a distance of 1.5 to 2 meters. Studies of critical radiation levels show that unbearable human pain occurs at 5 kilowatts per square meter. Spontaneous combustion of wood occurs at 12-13 kilowatts per square meter, and values as low as 7.5 have been reported.

Aren’t radiant heat considerations built into NFPA 80 glazing size area limits?

Simply, no. The recently revised NFPA 80 deletes size limits for glazing materials without considering radiant heat hazards. Only in Appendix J does it caution us to consider radiant heat when selecting glazing materials in large sizes. Again, the burden is on architects, contractors and code officials, who typically are not trained to assess radiant heat control factors and do not always know the relative performance capabilities of various glazing products, to make the appropriate choice of materials.

Can you tell which products limit radiant heat by their labeled ratings?

Sometimes. If you know the test standards well enough, you can. If you know that a glazing product was tested as a transparent wall, which includes temperature rise limits of 250F degrees, you can be confident that it limits the transfer of radiant heat.

However, products that do not limit radiant heat often carry a similar label to those that do reduce radiant heat. Even though a product is listed for a higher rating (i.e., 60-minutes and above) does not mean that it protects against radiant heat. If it does not protect against radiant heat, it cannot be used safely in wall applications; in windows and doors, yes, but not walls.

So, you have to educate yourself on the respective performance levels of products and the information is sometimes hard to discern. For starters, look carefully at the product literature, especially the small print, for any qualifications or limitations to product performance related to radiant heat transfer. Manufacturers should clearly disclose the fact that their products do not limit radiant heat even though they are rated for 60-minutes or more.

Glazing products that limit radiant heat are typically multi-layer laminates or insulated glass. In other words, they are thick in appearance. Monolithic (single layer) or single laminated products do not limit radiant heat transfer. Certain exceptional monolithics, such as SuperLite I-XL by SAFTIFIRST, dramatically reduce radiant heat transfer for a monolithic, but should not be used in any applications without prior AHJ (Authority Having Jurisdiction) approval given their limitations regarding direction and hose stream.

So what glazing products limit radiant heat?

• Insulated products, such as SuperLite II-XL, Pyrostop, Pyrobel, Contraflam, Swissflam, etc. -- products that are rated 60-minute plus to ASTM E119, limit temperature rise to 250F degrees and reduce radiant heat flux to 0 kilowatts per square meter.

• SuperLite I-XL – a window and door product that reduces radiant heat flux to one kilowatt per square meter at 60 minutes and is like products widely used in Europe that similarly limit radiant heat flux.

And, finally, what products do not limit radiant heat?

• Wired glass allows radiated flux on the unexposed side of 35-38 kilowatts per square meter at 37 minutes.

• Ceramics, such as FireLite and Keralite, allow radiant heat flux of 75 kilowatts per square meter at 60 minutes.

Remember the critical level for unbearable human pain is 5 kilowatts per square meter, and the auto-ignition of wood combustibles is 7.5-13 kilowatts per square meter.

![]()

Article published with permission from SAFTI FIRST Fire Rated Glazing Solutions (link to original article)