Author: Kalle Kaijanen | Glaston

Source: glastory.net

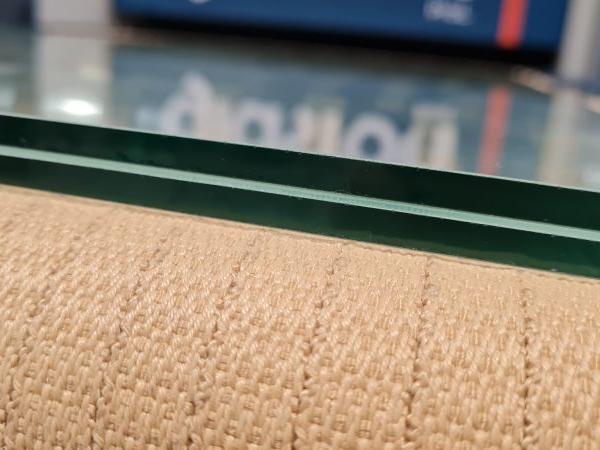

The rising preference for laminated glass, known for its safety features, is driving significant market growth. One notable trend in this market is the increasingly advanced technology available to improve product quality and production efficiency. Convection control technology is a key innovation in this area, addressing common challenges and enabling greater production yield of high-quality laminates.

The flat glass lamination industry is experiencing impressive growth. In 2023, the laminated glass segment of the flat glass market led with a share exceeding 41%. By 2032, this segment is expected to reach multimillion figures.

This growth has been driven by escalating safety regulations, growing extreme-weather concerns and the increasing use of laminated glass in applications such as balcony railings. As a result, more efficient and effective production processes are needed.

Challenges in high-strength glass lamination

Overheating the edges is one of the primary challenges glass processors face when producing laminated glass, especially high-strength laminates. Overheated edges can lead to premature edge sealing, trapping air inside the laminate and causing bubbles, a significant quality defect. The problem is most pronounced at the trailing edge of the glass, where air tends to accumulate during the lamination process. The continuously growing complexity of modern laminate compositions causes additional challenges when processing high-quality laminated glass.

Premature edge sealing highly affects the yield, increases waste and reduces production efficiency.

"Traditional methods of lamination typically rely on a combination of convection and radiation heating. However, these methods struggle to provide the uniform temperature control necessary for producing consistent high-quality laminates. The need for better control over the lamination process is obvious."

Innovations in laminated glass production

The first full-convection glass laminating lines established a new standard in the industry. Introduced around 2016, these became the most energy-efficient laminating lines on the market.

Convection control technology emerged in 2021 to further boost the quality and efficiency of glass lamination and make it easier to laminate even the most complex structures.

This innovative technology automatically adjusts the heating of the trailing edge of the laminate, preventing premature edge sealing. Glass processors can now achieve 95–98% good-quality laminates, a major improvement over the previous maximum of 88%.

Precision of convection control – regardless of glass type

The essence of convection control technology lies in its ability to maintain uniform heating across the entire laminate. By dynamically adjusting the airflow and temperature based on the position of the glass, the technology ensures that all areas of the laminate are heated evenly, with deviations of only 1 to 2 °C. This level of precision is difficult – if not impossible – to achieve with radiation heating.

"Stated simply, the system knows where the glass is going, directs heat accordingly and avoids overheating the edges."

One of the significant benefits of this technology is that the results are consistently good for any glass type being processed. This is true whether the glass is clear, coated, painted or a challenging glass, such as Low-E, which reflects heat away. Glass processors no longer need to create different heating profiles for each type of glass. This greatly simplifies the production process and reduces potential errors.

Keeping up with innovations

Because of the rapid evolution of the market, upgrading to the latest developments is crucial to maintain a competitive advantage in glass lamination.

Fortunately, any existing laminating line, regardless of its original heating technology or brand, can be upgraded with a full convection heating furnace and equipped with cutting-edge convection control.

What should we expect in the future?

The future of glass lamination is poised on the edge of even more exciting innovations. The increasing complexity of interlayers, changing regulations across the world and the quest for higher efficiency will drive new solutions.

"For instance, automation is becoming a critical focus area as the industry seeks to address the shortage of skilled labor. Technologies capable of automating various aspects of production are expected to play a significant role. These advancements will improve efficiency and consistency and make it easier to employ new workers."

Reaching higher yield

Recent convection control technology for flat glass lamination has dramatically improved the industry’s ability to efficiently produce high-quality, high-strength laminates. And glass processors can look forward to even greater yield, efficiency and overall product quality as technology continues to be developed.