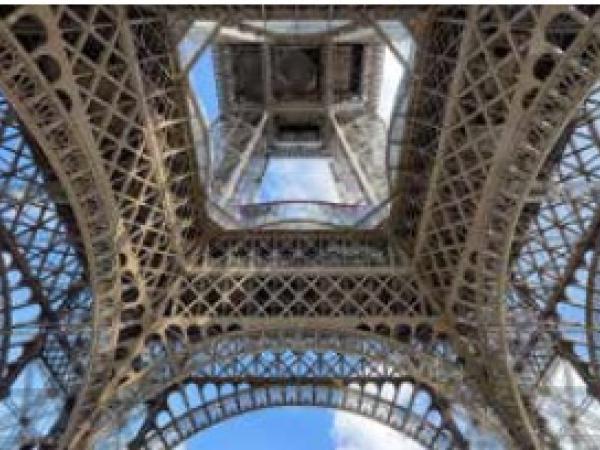

Architectural firm Moatti-Riviere was commissioned by SETE (the company that operates the Eiffel Tower) to transform the 5,000 square metre (54,000 square feet) first floor space into one of the most spectacular places to visit in Paris. The refurbished first floor of the Eiffel Tower, which opened in October 2014, now offers visitors a double attraction: an incredible view of the city, as well as a unique view of the Tower itself.

This was accomplished by installing clear glass guardrails around the Tower’s central opening and, behind these barriers, a path of transparent glass. At a height of 57 metres (187 feet) above the ground, visitors now have the impression of walking on air above the overhanging vantage point of the first floor – adding considerable appeal to this already popular tourist attraction.

At a height of 57 metres (187 feet) above the ground, visitors now have the impression of walking on air above the overhanging vantage point of the first floor – adding considerable appeal to this already popular tourist attraction.

The original opaque floor has been partly replaced by a 128 square metre (1380 square feet) glass floor. Laminated safety glass with SentryGlas® interlayer is installed in the first floor, in both the glass floor and the balustrades, which are inclined outwards.

RFR, structural engineers on the project, advised the architect on what was possible in terms of glass structures and were responsible for the design preliminary calculations for the glass floor, facades and balustrades, checking of contractors drawings and site supervision.

Niccolo Baldassini, Managing Director at RFR, commented: “For such a prestigious public building project, it was critical that all safety and security regulations were met. The Eiffel Tower is a muchvisited attraction and so we had to be absolutely certain that the crowded floor spaces were designed and tested to the most stringent building safety standards. The glass floor and balustrades were tested by the national organisation in charge CSTB: ATEX No. 1968.”

“The primary reason for choosing SentryGlas® interlayer for the glass floor and balustrades was its excellent post glass breakage performance, which ensures that the glass remains in place and has a residual resistance even if all the layers are broken, providing maximum safety for visitors.

We did consider using PVB as the interlayer, but this could not provide the post-breakage safety or thickness [weight] reduction advantages that SentryGlas® interlayer provides. In addition, for the glass balustrades, the transparency and open edge stability of SentryGlas® interlayer were also important factors,” he added.

According to Mr. Baldassini, RFR worked closely on the project with Bellapart, who was responsible for finalisation of the design, testing and installation of the glass floor and balustrades.

Nuria Guitart, project director at Bellapart, commented: “As well as its excellent post-glass breakage performance, laminated glass with SentryGlas® interlayer also offers excellent weathering in outdoor applications and allows large spans of glass to be used.”

“Weight of the glass was also limited by the structure itself. PVB interlayers were considered, but these could not give us the weight [glass thickness] reduction that we required for the first floor project. We also needed to preserve the transparency of the glass floor and balustrades, which again pointed to the use of SentryGlas® interlayer,” continued Guitart.

The 32 mm (1 17/64 in) thick glass floor had dimensions of 3.87 m x 0.7 m (12 ft 8.36 in x 2 ft 3.56 in) and comprised three layers: 10 mm (25/64 in) thick heat strengthened glass, 1.52 mm (60 mil.) thick SentryGlas®, 10 mm (25/64 in.) thick heat strengthened glass, 1.52 mm (60 mil) thick SentryGlas® and an 8 mm (5/16 in.) thick tempered anti-slip top layer of glass with a dot frit pattern to keep the glass as transparent as possible but still safe to walk on.

The glass balustrades comprised a lower panel and an upper panel. For the lower panel, the glass structure comprised three layers of 6 mm (15/64 in.) thick heat strengthened glass, 1.52 mm (60 mil.) thick SentryGlas® interlayer, 6 mm (15/64 in.) thick heat strengthened glass; 1.52 mm (60 mil) thick SentryGlas® interlayer and 6 mm (15/64 in.) thick toughened glass. The upper panel of the balustrades comprised two layers of 8 mm (5/16 in.) thick float glass and 1.52 mm (60 mil.) thick SentryGlas® interlayer.

According to Ms. Guitart, multiple tests were carried out on the laminated glass with SentryGlas® interlayer prior to installation. These tests included impact tests; uniform load/deflection tests where the glass was heated up to 30 °C (86 °F) and post-breakage tests, where the overall glass pane stability was verified in case of glass accidental damage.

The benefits of laminated glass with SentryGlas®

Worldwide, there is an increasing trend in the use of glass in flooring and balustrades in retail, commercial/office, private and public buildings. This trend is being driven by the increased desire to provide more open plan, unique, stylish designs. In flooring, the main function of SentryGlas® interlayer is to provide a high strength, stable, safe platform for people to walk or stand on, as well as retaining the glass in place if it breaks.

Benefits of laminated glass with SentryGlas® in flooring applications:

- Laminated safety glass with SentryGlas® ionoplast interlayer remains intact even if broken.

- Easily meets the high load requirements of flooring and walkways, in terms of its strength and deflection properties. Very high stiffness compared to PVB .

- SentryGlas® is able to fulfil the high architectural safety standards at a reduced thickness compared to laminates with PVB . This means supporting structures used for the glazing can often be designed significantly lighter and therefore much more subtle in terms of their appearance.

To learn more about pushing the limits of glass, visit

www.sentryglas.com