Date: 9 April 2018

“Kuraray offers a wide range of unique coating products that offer design, performance, cost and environmental benefits to manufacturing customers, along with the end-consumer,” said David Steinberg, Director of Elastomer Sales at Kuraray.

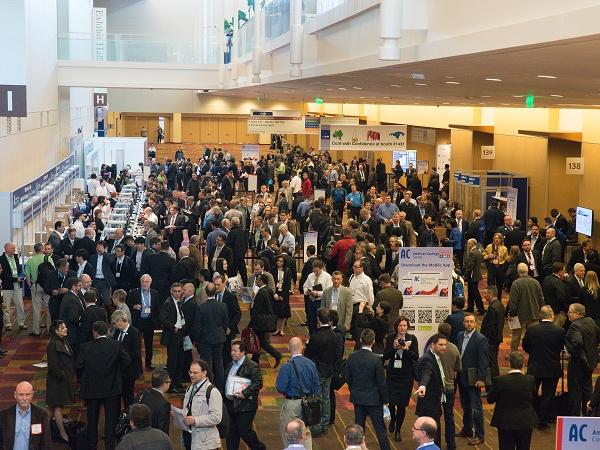

“The American Coatings Show is growing by leaps and bounds, with more attendees coming with each installment of the biennial show. It presents us with a dynamic opportunity to educate current and prospective customers in the coatings, paints, sealants, construction chemicals and adhesive industries with how our technologies can take their products to new levels of success.”

At ACS, Kuraray will highlight several of its product lines, including:

- Advanced Chemicals – Kuraray will feature polyols and diols, which are well suited in many applications as constituents of polyurethane resins. Along with Kuraray’s other chemical products, they’ll feature MMB (3-methoxy-3-methyl-1-butanol), a unique and useful fine chemical produced by Kuraray which has received a lot of attention in many industrial fields due to its low toxicity and good biodegradability. Kuraray is the first in the world to commercialize a one-step synthesis method for isoprene monomers, and offers products made using various C4 and cyanide derivatives.

- Polymers – As the first entity in the world to bring polyvinyl alcohol (PVOH) synthetic fiber to market, Kuraray has numerous PVOH-based resins it will highlight at the ACS show. Some of the most prominent include Kuraray POVALTMand ELVANOLTM, known for their excellent film formation, emulsifying power, and adhesion to substrates. With a wide range of hydrolysis levels, stable quality, low ash and VOC content, they are used throughout a variety of industries. One specific resin on display will be Elvanol LPE703, a new grade of water-soluble PVOH. Kuraray will also educate attendees on other polymers including:

- EXCEVALTM, the company’s brand name for special water-soluble, ethylene vinyl-alcohol (EVOH) copolymers. This fine-grained, free-flowing white powder is transparent, strongly adheres to metal and is resistant to organic chemicals. It is used frequently in barrier coatings of film, paper, and other substrates from an aqueous solution.

- Kuraray’s MowitalTM (polyvinyl butyral) is a building block for many specialty coatings and films. With excellent adhesive and film-forming properties, strong binding power and outstanding transparency, MowitalTM is an unquestionably versatile thermoplastic material. It is most frequently used in inter-layers for safety glass, paints, lacquers, and varnishes (i.e., primers for metals and anti-corrosion paints), printing inks, temporary binders and adhesives.

- Elastomers – Kuraray offers four different kinds of elastomers.

- SEPTONTM is a series of styrenic-based thermoplastic rubbers that can be used over a wide range of temperatures and hardness levels. It offers strong tensile strength and elasticity, better resistance to heat, weather and ozone, and is recyclable. One particular SEPTONTM product that will be featured at the show is SEPTONTM 8004, a spray coating used in the roofing industry offering lower viscosity and molecular weight grades.

- KURARITYTM is a new acrylic, thermoplastic elastomer used in spray applications. It offers excellent clarity, removable film, weather resistance, self-adhesion, has no volatile organic compounds (VOC) and good compatibility with other polar materials.

- HYBRARTM is a tri-block copolymer that exhibits high vibration damping and shock absorption properties. With applications across more than a dozen industries, HYBRARTM is available as durable hydrogenated and non-hydrogenated grades, and can be processed in films, tubes and injection molding.

- Kuraray Liquid RubberTM (K-LR) is a viscous rubber additive used in kneading and cross-linking rubber when shaping and processing. The K-LR line includes Liquid Isoprene Rubber (LIR) and Liquid Butadiene Rubber (LBR). These synthetic rubbers are colorless, transparent and almost entirely odorless. Using K-LR products during the rubber compounding phase significantly reduces processing time while maintaining the rubber compound’s physical properties, which results in lower processing costs. It is commonly used in tires, belts, hoses, as well as to produce high-performance coatings, adhesives and sealants.

To learn more about Kuraray’s product portfolio and see custom samples up close, visit Booth 2355 during the show.

More detailed information is available online at www.kuraray.us.com.

600450

600450

Add new comment