Date: 14 April 2025

In flat glass processing, even the smallest defects in the glass can lead to complaints or costly downtime. Modern scanners are essential for the early detection of these defects. The so-called dark field channel - a special camera perspective with laterally incident light that makes the finest structures on the glass surface visible - is particularly effective here. Systems such as the Viprotron Temper Scanner and the Quality Scanner use this technology to take quality control to a new level.

What is a dark field channel for detecting defects in glass?

A dark field channel uses light that is incident from the side and passes over the glass surface. Unlike conventional bright field illumination, where the glass is illuminated from the front and evenly, dark field creates a strong contrast between the defect and the background. This makes it possible to highlight defects in the glass that would be missed by conventional systems, such as hair scratches, grinding marks, roller marks or adhesions.

This special perspective, which simulates sunlight from a flat angle, also reveals defects that would be noticed by the customer later - for example, on glass facades in certain lighting conditions.

Why conventional systems miss defects in glass

Standardised inspection systems without a dark field channel typically use only one camera axis, often in combination with bright field illumination. This can detect many defects, but not all defects in the glass. In particular, low contrast, fine lines or slight opacities are difficult for these systems to detect. This leads to two problems:

- Defective glass passes unnoticed through the production process.

- Complaints from end customers arise because defects in the glass suddenly become visible under certain lighting conditions.

- This is where the dark field channel comes in: It provides an additional perspective that enables the detection of glass defects - and thus significantly increases inspection accuracy.

How the dark field channel makes defects in the glass visible

The comparison images provided by Viprotron make it clear: a fine scratch is barely visible in bright field, but clearly visible in dark field. This is because defects in the glass scatter the incident light from the side - and thus appear as a bright signature against a dark background.

The visual result:

- Bright field: weak contrast

- Dark field: clear, bright line on dark background

- Reflection channel: complementary view, but less sensitive to defects

- This combination of different channels produces a more complete image - and increases the chance of clearly identifying defects in the glass.

Advantages of the dark field channel in glass inspection

The use of a dark field channel brings a number of improvements to quality control, particularly with regard to defects in glass:

- Higher detection accuracy The additional angle of view allows the detection of even very small or structured defects in the glass. The combination of multiple inspection channels (bright field, dark field, reflection) creates a comprehensive defect image - ideal for automatic classification and sorting.

- Early detection of defects in the glass By integrating the dark field channel directly after the tempering furnace or in previous process steps (e.g. edge processing or insulating glass production), defects in the glass are detected before they pass through further production steps. This saves material and machine time and prevents rejects in later process stages.

- Fewer customer complaints Many complaints are caused by defects in the glass that are only visible to the end customer - for example, due to lateral sunlight. By simulating these lighting conditions in the dark field, these defects are detected and eliminated during production.

- More efficient production through automated detection High detection reliability reduces the need for manual rechecks. The scanner provides consistent and objective detection of glass defects - around the clock and independent of operators.

The Viprotron Temper Scanner: Customised solution for defects in glass

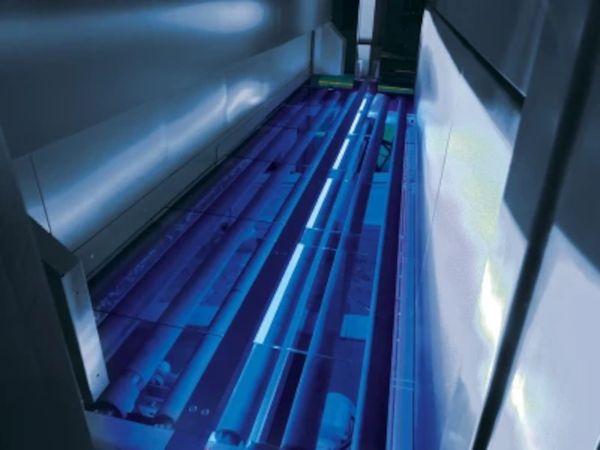

A prime example of the successful integration of the dark field channel is the Viprotron Temper Scanner 5D. This system has been specifically designed for optical inspection after the ESG process. It combines state-of-the-art technologies:

- Bright field camera for transmitted light inspection

- Dark field camera for lateral defect detection

- Reflection channel for detection of layer defects Measurement of all types of optical distortion (e.g. waviness, edge buckling)

- Detection of anisotropies

The dark field channel significantly improves the detection of the finest defects in the glass. The scanner detects white haze that would remain hidden with conventional technology - a real added value for demanding customers.

The introduction of a dark field channel in glass inspection makes it possible to detect glass defects more accurately and reliably. The result: fewer rejects, fewer complaints, greater customer satisfaction - and ultimately more economical processes.

With the Temper Scanner 5D, Viprotron offers a powerful solution that picks up where standard solutions fail. The combination of multi-channel inspection and decades of experience in glass inspection makes Viprotron a strong partner for companies that don't want to give glass defects a chance.

600450

600450

Add new comment