Date: 26 April 2017

Market leadership is no accident. Schlotterer Sonnenschutz Systeme GmbH relies successfully on well-trained employees, comprehensive automation, and the holistic software system A+W Cantor.

A state-of-the-art powder coating system ensures a perfect finish for the external blinds. According to Managing Director DI Peter Gubisch, all products are in the customer’s hands within 10 days.

Innovation for top-notch products

Intelligent sun protection demands the greatest readiness to innovate. Schlotterer products such as the current BLINOS ROLLO or the daylight external blinds RETROLux come from the company’s own 12-person development department, which works together with renowned external experts.

2012: In Adnet, a new building is put into operation, which doubles production space and significantly expands capacities. 30 new jobs are created. Total investment: EUR 15 million. At the same time, Schlotterer successfully completed the IT project “EDGE” that it started in 2010. The whole company is networked with more than one hundred A+W Cantor monitor workstations, forty-three in the commercial area and seventy A+W Cantor Production stations in production and shipping.

Managing Director Wolfgang Neutatz, “We set ourselves up for the future with a comprehensive EDP solution and we have never looked back. The A+W Cantor system offers us 100% availability and works absolutely reliably day after day.”

Highly-automated production

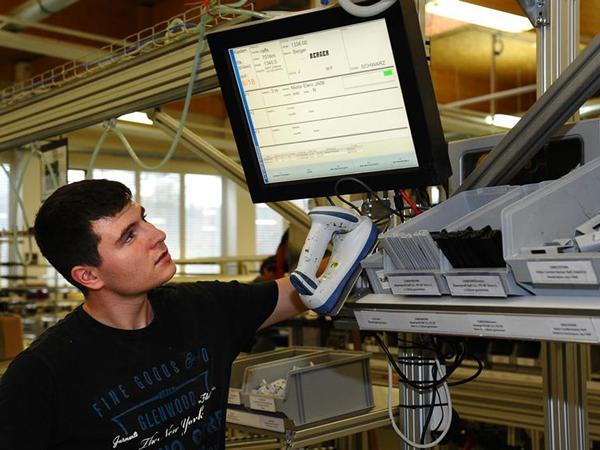

You would look in vain for paper in Schlotterer’s production areas. With the help of A+W Cantor production monitors and continuous bar code registration, the semi-finished products are steered reliably through production and assembled at the end into finished exterior blinds or other Schlotterer products.

While everyone is talking about Industry 4.0, important parts of this concept have already been implemented at Schlotterer. The decisive productivity advantage, according to DI Peter Gubisch, is, in addition to the high degree of digitalization of the machines, the comprehensive networking of the whole company with holistic A+W Cantor industry software, from order entry to production and machine control, on through to shipping. All information is available at all times wherever it is needed.

Romana Eibl, Inside Sales, “The processes have been speeded up a great deal with the A+W Cantor software; the exchange between departments works much faster and more reliably. Thanks to ongoing status updates, we always have a reliable overview of the state of production of each order and each individual product.”

From the order form to the Webshop:

A+W iQuote at Schlotterer

Frequently, people overlook the fact that Industry 4.0 does not begin in the production facility: instead, company-spanning, highly mobile communication in the commercial sector is the prerequisite for successful automated production. For many Schlotterer customers, in the future this communication will begin in the Webshop

Wolfgang Neutatz names some of the most important advantages, “Our customers cannot make any more mistakes with A+W iQuote. The entire order runs through a restriction check based on our master data. We get a complete technically correct order; questions and long-winded clarifications on the telephone are no longer required. This means greater efficiency in the entire order process.”

A+W iQuote guides the user intuitively through the configuration process, right on through to the completely-calculated quotation including graphically-appealing drawings.

In order to make the Webshop still more attractive, Schlotterer grants customers who place their orders using A+W iQuote a 1% bonus on the order total – as a thank-you for the reduced effort, time saved, and increased process reliability.

But the customer has even more advantages: ordering with A+W iQuote provides the greatest flexibility and mobility. It does not require any installed ordering software or an office workstation, but rather only an iPad or other mobile end user device on which he can use a Web browser.

Schlotterer’s trade partners can run through product variants, prices, and other options with the end customer on-site and then place an order: thus, Industry 4.0 could even begin in the customer’s living room – but it does not have to, because the great transparency of the Web configurator should assist the sales partners first and foremost.

"Schlotterer’s entire master data logic," explains Project Manager Martin Harold, "is mapped seamlessly in A+W iQuote.

This complete integration enables secure and complete product configuration in the Webshop. However, in the end, the outstanding project implementation is due to perfect cooperation with the A+W Cantor team – here the chemistry is just right!"

On our references page you can find further information about the company Schlotterer!

600450

600450

Add new comment