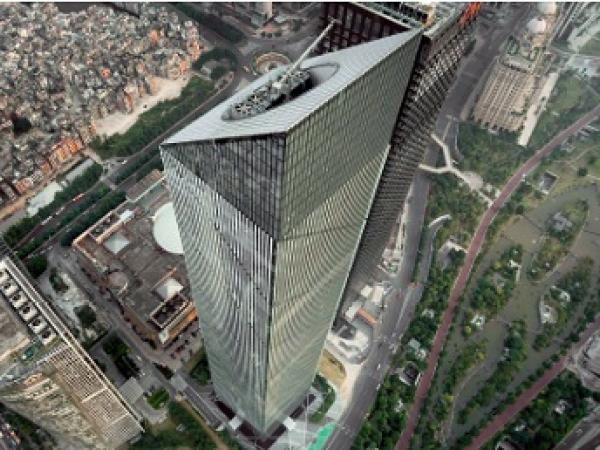

At 303 m, the Leatop Plaza is Guangzhou's fifth tallest building. Of the total façade area of 159,500 m2, SentryGlas® was used over 63,000 m2, for its strength and energy-saving capabilities.

The visual appeal and brightness of the building is primarily down to the use of white ceramic glaze in over 70% of the hanging element of the overall façade. The façade also offers significant beneficial functional attributes thanks to the use of DuPont™ SentryGlas® in its laminated construction.

At 303 m, the Leatop Plaza is the city's fifth tallest building. It has 69 floors in total, 5 of which are below ground, 35 elevators and 838 parking spaces. Designed by a team including more than 10 design firms, the developer invested some 2 billion RMB in the project, which was finally opened in 2012. Of the total façade area of 159,500 m2, SentryGlas® was used over 63,000 m2.

Secured to the building to look like scales, the 1.95 x 4.2 m ceramic glazed laminated panels comprise 8 mm HS low-iron + 1.52 SentryGlas®+ 8 mm HS low-iron glass + air + 8 mm low-iron glass. The panels exhibit a partial open-edge design, with 0.5 m of their 1.95 m width hanging out in the open. The architect took this approach for multiple reasons.

First to improve the façade's energy-saving capabilities; as the projecting façade acts as sun louver, helping to decrease energy using by 5%. Second, for aesthetic reasons, the scale façade looks white and transparent making the building brighter than any of the surrounding buildings. Finally there was a strict requirement concerning durability and delamination. Any potential panel failure would have led to the design being rejected.

.jpg)

SentryGlas® played a key role; as well as its compatibility with the ceramic material it has also seen deployment in many energy-saving installations around the world. Finally, its open-edge durability is very impressive, giving the architects and owners the confidence they need relating to the open edge design. According to the lead architect: "We were looking for a solution that offered enough durability for this design. And we finally found the answer in the form of SentryGlas®."

The designers and consultants also looked at other solutions, including those which deployed PVB, but they were doubtful about its durability and its compatibility with the ceramic glaze. For decades, interlayers made of polyvinyl butyral (PVB) have been the industry standard when producing laminated safety glass. Architects are well aware of the possibilities and limitations of such glass when used extensively in façade engineering, for roofing and window panels.

.jpg)

In contrast, SentryGlas® enables an entirely new approach because the interlayer is over 100 times stiffer and five times stronger than PVB. As a consequence, there is an almost perfect transmission of load between two laminated sheets of glass, even at high temperatures, leading to the excellent flexural behaviour of the glass when under load – also under direct sunlight in high summer. Accordingly, laminates with SentryGlas® show less than half the rate of deflection when compared to laminates with PVB, when under the same load, and thus almost the same behaviour as monolithic glass of the same thickness.

.jpg)

REGIONAL CONTACT CENTERS FOR DUPONT™ SENTRYGLAS®

DuPont Glass Laminating Solutions

Wilmington, Delaware U.S.A.

Telephone +1 302 774 1161

Toll-free (USA) 800 438 7225

Fax +1 302 892 7390

DuPont do Brasil, S.A.

Barueri, Sao Paulo Brasil

Telephone +55 11 4166 8542

Fax +55 11 4166 8720

DuPont China Holding Co., Ltd.

Pudong New District, Shanghai

Telephone +86 21 3862 2888

Fax +86 21 3862 2889

DuPont de Nemours Int’l. S.A.

Geneva, Switzerland

Telephone +41 22 717 51 11

Fax +41 22 717 55 00