Author: Luc Moeyersons

This information corresponds to our current knowledge on this subject. It is offered solely to provide possible suggestions for your own experimentations. It is not intended, however, to substitute for any testing you may need to conduct to determine for yourself the suitability of our advice for your particular purposes.

This information may be subject to revision as new knowledge and experience become available. Since we cannot anticipate all variations in actual end-use conditions, LAMI-Solutions makes no warranties and assumes no liability in connection with any use of this information.

Nothing in this publication is to be considered as a license to operate under or a recommendation to infringe any patent right.

TABLE OF CONTENTS

1. Introduction

1.1. Stages of production

1.2. Comments

2. Preparation of glass

2.1. Stages of production

2.2. The glass

2.3. Unloading the glass

2.4. Cutting the glass

2.5. Breaking out of the glass

2.6. Seaming

2.7. Washing

2.8. Separating Agent

2.9. Ceramic band

2.10. Coated glass

3. Bending the glass

3.1. Sag bending

3.2. Press bending

3.3. Press assisted bending

4. PVB Preparation

4.1. Stages of preparation

4.2. Interleaved – Refrigerated

4.3. Packaging

4.4. Unwinding the roll

4.5. Adhesion & Moisture control

4.6. Stretching

5. Assembly

5.1. Preparation of glass

5.2. Assembly room

6. Prepressing

6.1. A look at different processes

6.2. vacuum ring process

6.3. vacuum bag process

6.4. Roller process

6.5. Ovens in use

6.6. Edge sealants

6.7. Use of clips

6.8. Windscreen stacking

7. Autoclaving

7.1. A look at different autoclaves

7.2. The purpose of autoclaving

7.3. Operational parameters

7.4. Risk of volatiles evaporation & autoclave fires

7.5. The ideal “practical” autoclave cycle

7.6. Possible autoclave cycle improvements

7.7. Recommended precautions

8. Windscreen finishing

8.1. Encapsulation

8.2. Trimming of excess PVB

9. Inspection

9.1. Defects in the glass

9.2. Defects in the PVB

9.3. Defects in the laminated glass

9.4. the shape of the windscreen

9.5. Laboratory testing

10. Lamination Defects

10.1. Bubbles

10.2. Bubbles: Rule of thumb on root cause

10.3 Delamination

4. PVB Preparation

4.1. Stages of preparation

4.2. Interleaved – Refrigerated

Refrigerated PVB needs to be stored/transported between 4 and 10 °C. The higher temperature limit is to prevent the PVB to stick to itself creating blocked rolls.

If stored at lower than 4°C temperature, there is the risk of dew formation even in (30 % ) RH controlled clean rooms.

Interleaved PVB needs to be stored/transported, by preference below 25 °C to prevent surface roughness deformation.

If stored at higher temperature, it is advisable to store the rolls (for minimum 24 hours) prior to usage, at 20 °C.

In former times, Sodium bicarbonate (NaHCO 3 ) powder was used for non refrigerated rolls. This had to be washed/rinsed off and afterwards the PVB film had to be reconditioned.

4.3. Packaging

The rolls are packed in OPA bags or double PE bags and sealed with plastic end-caps, to prevent moisture pick up by the hygroscopic PVB.

The OPA (Oriented Polyamide) bags are barriers against moisture penetration, at least the central aluminium film is. The aluminium foil is protected from oxidation by a Poly Ethylene film (inside) and on the outside an “Oriented Poly Amide” film to reduce the risk of tearing of the bag.

Most commercial PVB’s are delivered with a moisture content between 0.35 and 0.55 % ; this to ensure a stable adhesion between the PVB and the glass.

The use of OPA bags is recommended (+ plastic end caps), as protection against moisture, even for partially used rolls.

Recommended temperature for storage of refrigerated PVB’s : 7 °C.

The PVB is wound on plastic cores (PolyEthylene, PolyPropylene or ABS polymer) in order to ensure:

- The elimination of static electricity

- A PVB which is not contaminated (provided that the core is not damaged)

Plastic cores are part of the industry packaging waste reduction program. Suppliers take back all plastic packaging components, except stretch wrap and protective bags.

4.4. Unwinding the roll

◦ Risk of blocking (store below 10 °C)

◦ Recommendations:

- After unwinding and cutting the PVB film, allow the blanks to rest for 16 to 24 hours before use.

- This will allow relaxation from eventual stretching during unwinding.

- Store a maximum of cut blanks equal to a roll of 250 meters in a pile.

4.5. Adhesion & Moisture control

(Adhesion is influenced by the moisture content).

The relation between the moisture content of the PVB and the relative humidity.

The fractional approach to moisture equilibrium (0.76mm PVB thickness) at ambient temperature.

The fractional approach to moisture equilibrium (0.76mm PVB thickness) at different temperatures

The moisture pick-up during short exposures to 50% relative humidity.

The relation between the adhesion and the moisture content of the PVB.

The relation between the adhesion and the moisture content of the PVB for different thicknesses and water content.

CSS correlation to Moisture Content and PVB Thickness (B5)

Doubling the PVB thickness reduces the CSS adhesion result to app. 66 % of the original value.

Other factors:(influencing level of adhesion)

◦ The cleanliness of the glass surfaces (wash water quality and drying method)

◦ The tin content of the ‘float’ glass.

The relation between the adhesion and the impact of the 2.27kg ball (5 pound).

ECE R43/Temperature:23 deg.C

lamination process (conditions/adhesion) and glass thickness.

4.6. Stretching

4.6.1. Reason:

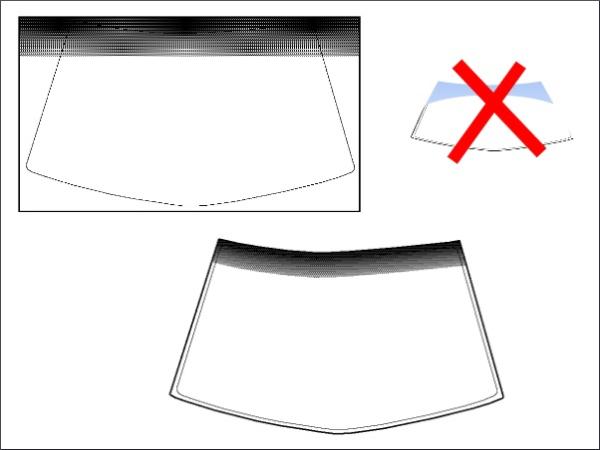

- Cosmetic. (The shade band should follow the roof line of the windscreen, avoiding a “frowny appearance of the shade band”, once installed in the car)

◦ Saving in PVB loss (trimmings).

If the blank is shaped correctly the surface area gain can be up to 15%

BUT :

Both the thickness and the ball drop performance will be variable from (originally) non-stretched PVB.

4.6.2. Warping of the blanks:

- The PVB sags under gravity and temperature.

- The PVB needs processing for 10 to 30 minutes at 80-110 deg. C

- Advantages:

- Low investments.

- Possible with refrigerated PVB.

The thickness is not significantly affected

- Disadvantages:

- Slow and labour intensive.

- Conditioning of the PVB required after stretching.

- High risk of defects (wrinkling).

4.6.3. Expandable mandrels:

The PVB is wound hot, expanded, heated, etc.

Interleaved PVB is necessary

(the stretchability of interlayer and interleaving film is important)

Stretching cycle of 60 min. at 100 deg. C

- Advantages:

- Simplicity

- Disadvantages:

- Conditioning necessary.

- The surface pattern is altered.

4.6.4. Stretching on a fixed cone:

◦ The interleaved PVB is wounded under high tension onto a fixed pitch cone.

- Advantages:

- Simplicity

- Disadvantages:

- Conditioning necessary

- The surface pattern is altered.

4.6.5. Continuous stretching:

- FORD Type A:

- The PVB is continuously stretched over a single variable pitch cone.

- Process is limited to 10 meters/min.

- Temperature required is approximately 100 deg. C

(to avoid shrinkage of the stretched PVB-blanks)

- Advantages:

- Speed

- Can be used for clear PVB and PVB with shaded band.

- No further conditioning necessary (if correctly set).

- A change in bending radius is easily achieved.

- Disadvantages:

- Dimensional stability is reduced.

- Variation in thickness.

- High investment.

- Risk of PVB drying.

4.6.5. Continuous stretching:

- FORD Type B, PPG’s CVS:

- The PVB is continuously stretched over a fixed-pitch cone array. Some of the cones are used for cooling.

- A change in radius is achieved by changing the position of the film on the cone.

- Very high investment.

- No significant advantage over the Ford Type A.

4.6.5. Continuous stretching:

- Saint-Gobain, Ayrox system:

- The PVB is continuously stretched over a system with variable heat and uniform stretching.

- Mirror image of variable stretching with uniform heat.

Cut from PVB roll With Shade band

The blanks are cut afterwards from the wound-up roll in a rectangular shape but due to the shrinkage variability, the blanks change (over time) into an arc form.