Date: 30 July 2018

The commercial building in quiet surroundings in Zollikerberg near to Zürich was built in the early 1970s. With the recent modernisation, Zürich-based practice Schäublin Architekten AG has demonstrated in impressive fashion how an ageing building can be upgraded and given a new lease of life at a reasonable expense.

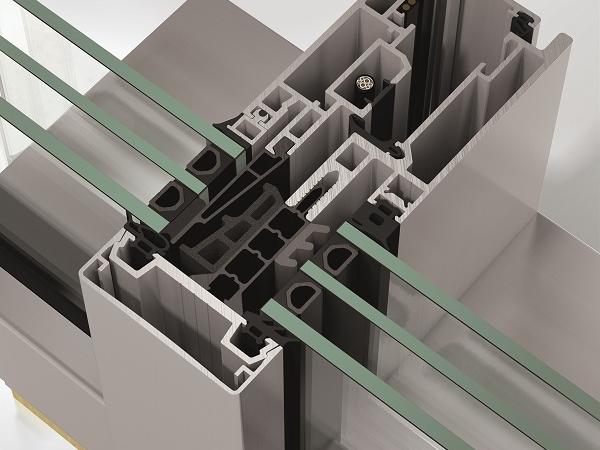

The ribbon windows from the new Schüco FWS 60 CV façade system contribute significantly to the building’s contemporary appearance.

Southeast of Zürich, Zollikerberg underwent a veritable construction boom from the late 1960s to the early 1970s. In addition to countless houses, a number of exclusively commercial premises were also built, including the five-storey building on Bühlstraße.

It was constructed as a skeleton structure with spandrel units made of pre-cast concrete components and generous window openings – estimated by Silvan Harringer, the architect responsible for the modernisation works as a project manager, to make up approximately 50% of the façade.

The profiles are machined in the Surber Metallbau AG workshop on the Schüco processing centre.

With the building and its somewhat plain windows out of keeping with contemporary architecture, it was determined to give the property a facelift at a reasonable expense, especially as the windows were in need of renovation. To this end, the façade was cleaned and waterproofed and all the windows and external doors were replaced.

In their search for a flush façade system that nevertheless allowed window vents to be installed, the architects discovered the new Schüco FWS 60 CV façade profile system. With the visibly slimline aluminium mullion/transom façade system for ribbon windows, they were able to fulfil both their design expectations and the requirements for a high level of sound reduction and optimum thermal insulation.

Concealed vent impresses everyone involved

CV stands for “concealed vent”. The FWS 60 CV façade system is distinguished by window vents in the mullion/transom structure that cannot be seen from the outside when they are closed. The unobtrusive design therefore blends discreetly into the existing building whilst presenting an innovative appearance.

The ribbon windows, which are fitted with a window sill, are surface-mounted on the wall spandrel and are fitted with adapter profiles and panels at the top and connected to the ceiling. As a supporting measure, the ceilings were thermally insulated in the attachment area. The field division was kept uniform all the way round the building.

The axis dimension of the profiles measures 950 mm in width and 1920 mm in height. Only the windows on the top floor, which might conceivably be used for residential purposes, are kept slightly lower.

Every second glass field is fitted with a side-hung vent, whilst the intermediate fields and corner units have fixed glazing. The corners are profile-free in the vertical direction, i.e. designed as “all-glass corners”. All the units are fitted with high-quality triple insulating glass.

Preparing to bond the outer frame using special mitre adhesive.

Good leasing prospects thanks to optimised indoor climate

In choosing a colour, the architects decided on the “dark outside, white inside” combination, which is en vogue in contemporary architecture. However, in addition to the visual upgrade to the building, the newly fitted windows also reduce heating requirements and energy costs.

Moreover, they improve sound reduction and increase thermal comfort. All in all, the modernisation work will give the property good leasing prospects and make for happy lessees for a long time to come. The investment in the value retention of the building will therefore pay off in the long run.

Preparatory work: an outer frame on the left, a vent on the right.

Project details

Project: Bühlstrasse 1, Zollikerberg

(local authority of Zollikon, Switzerland)

Architect: Schäublin Architekten AG, Zürich

Window / façade: Surber Metallbau AG, Dietikon

Profile system: Schüco, FWS 60 CV

Profile supplier: Jansen AG, Oberriet, Switzerland ; Schüco International KG

The tested and cleaned glazing is lifted using the suction device.

Product information

Schüco FWS 60 CV (Concealed Vent) façade system

In recent years, ever-increasing demands for sound insulation and thermal insulation have led to ever more solid window profiles. It seemed that technical requirements could not be combined with a consistently elegant frame system.

The Schüco FWS 60 CV (Concealed Vent) façade system provides a solution for ribbon windows that combines the narrowest face widths with maximum functionality and the best possible thermal insulation.

With a face width of just 60 mm, the innovative system generates maximum transparency due to the seamless integration of vent and load-bearing structure. Fixed fields and opening units are indistinguishable from the outside. Only on the inside do a slender, flat shadow gap and the window handle betray the presence of the opening units.

Once inserted, the glass is sealed to the frame on all sides. The sealant is determined on the basis of the Schüco technical specifications and is dependent on the materials used in the glass edge seal.

Two basic depths combined with the attachment to building structure for individual use allow for the widest possible range of applications with very simple installation, from traditional and storey-height ribbon windows to punched openings.

The system achieves maximum façade transparency with floor-to-ceiling side-hung vents up to a unit size of 3 m (up to 3.20 m with special approval). The Schüco TipTronic SimplySmart concealed fittings system can be used for mechatronically controlled vents.

In order to install toplights and bottom lights individually, a sash bar profile is integrated into the outer frame units such that the sash bar blends seamlessly into the entire system with a face width of just 60 mm. Additional system components enable the flexible attachment of sun shading systems to reduce cooling loads.

Function check in the workshop. The frame and vent were assembled in the horizontal position.

Product benefits

Energy

- Ucw value of 0.86 W/(m²K) for unit dimensions, for example, of 1.2 m x 2.5 m with a Ug value of 0.7 W/(m2K)

- Uf value as low as 1.5 W/(m²K) including screw factor with 50 mm glass

Design

- Slimline profiles with an identical external appearance of the vents and fixed glazing

- Fusion of vent and load-bearing structure: additional insert outer frame not required

- Vent and outer frame flush-fitted on the inside with minimal shadow gap

- Side-hung, turn/tilt and tilt-before-turn windows can be designed with Schüco AvanTec SimplySmart fittings

- High level of convenience owing to mechatronically controlled opening units with Schüco TipTronic SimplySmart

- Can be used for traditional, storey-height ribbon windows including safety barriers and punched openings

- Individual design options with toplights and bottom lights

Security

- Burglar resistance to RC 2

- Tested safety barrier

Enhanced functions

- High-performance external, central and internal gasket system: can be used in a façade environment, even with the highest requirements in terms of wind loads and watertightness

- New spandrel glazing completely integrated in the profile (French balcony) for slender integration in applications with safety barrier requirements

- Flexible attachment of external sun shading systems to reduce cooling loads

Interview with the fabricator

Simple, economical fabrication process

What impressed Daniel Koller, fabrication team leader at Surber Metallbau AG, was that the FWS 60 CV façade system was not only visually appealing, but also simple and economical to fabricate. The infrastructure of the factory is set up to optimise the fabrication process in terms of orders – from cutting and machining the profiles to assembly, installation, interim/final storage, and transportation.

“Although we were fabricating this new system with the slimline frame and vent profiles for the first time, everything went smoothly,” explains Daniel Koller, adding: “The system is very well designed and is easy to process, even for beginners. It was only on the large, slimline vent frames that we first had to get used to installing the glass. We were all the more amazed by the high level of stability of the individual vents at the end.”

Daniel Koller, fabrication team leader at Surber Metallbau AG.

Mr Koller, Surber Metallbau AG is the first Swiss company to build the Schüco FWS 60 CV façade system. What were your experiences of this pioneering work?

The response from our employees, including me, to manufacturing the façade units was very positive. They were easy to handle and cleverly thought-out down to the last detail. The system guarantees a high degree of modularity with maximum flexibility.

What do you see as the difference compared to fabricating traditional vent systems?

The principle is quite different. The outer frame is only half as wide as for a standard mullion/transom profile and the vent profiles are narrower and lighter. This requires a little more care during the various machining processes.

How do you rate the individual production steps?

It was very easy to prepare the profiles and assemble the vents and outer frames. Installing the prepared Schüco AvanTec SimplySmart fittings also requires minimal effort.

What particularly impressed you?

I found the precise alignment (90°) of the vent prior to bonding to the glass a new and very clever solution.

We set the purpose-built, four-part frame jig on a tabletop, measured it as accurately as possible, aligned it and fixed it in place. Then we were able to put the individual vent frames into the frame jig, align them to the millimetre using the adjustment screws, clean the insulating bar, then insert and bond the glass using the indoor crane – with the help of glazing aids. All in all, a simple process. Afterwards we left the individual, glazed window vents lying down to dry.

Are there any aspects of production that you would advise your industry colleagues to be especially mindful of?

Not really in terms of production, more in terms of planning. We agreed with the architect to use an external cover cap of only 12 mm for this project. The system drawings from Schüco specify 18 mm. I would advise choosing a cover cap with a depth of 18 mm. The cover cap with basic depth of 12 mm that we used resulted in more work to channel the drainage through all of the levels.

600450

600450

Add new comment