Date: 12 April 2018

Warm Edge insulating properties, which bring important economical savings, are the reasons for the growing success of this kind of profile. As glassworkers know, the bending of plastic profile is an extremely delicate operation which requires precision and attention.

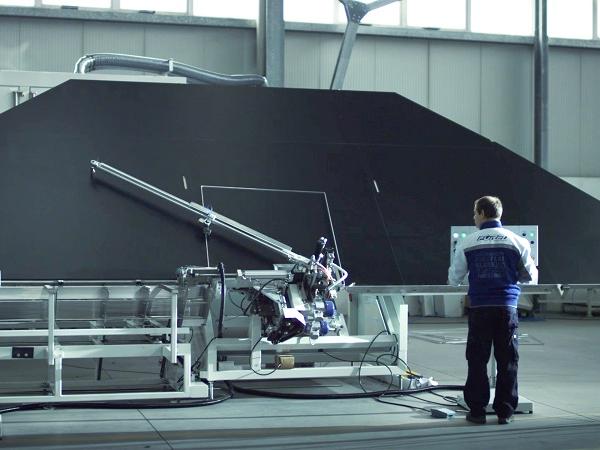

FOREL developed and upgraded its Automatic Profile Bender (ART. PBA632) to cater to different needs and typologies of material. The Profile Bender can now support the profile during the processing, thanks to the special Smart Arm (an exclusive FOREL patent). The arm works to avoid the risk of breaks or deformations when working with larger sizes.

This solution offers high productivity, quality and no risks of damage to the material.

Specific improvements have been developed to obtain a better bending process which offers two different results:

- The classical internal fold;

- An internal fold of 90°, visually identical to the “corner keys” (but without thermal dispersion in the corner) or to the welding junction (but with faster production).

The calibration of the bending is managed by a software, which ensures a complete control and precision of the angle.

600450

600450

Add new comment