Via Trieste, 13

Tribiano 20067 MI

Italy

Fenzi Spa

Find us on:

Fenzi is the worldwide leader in chemicals for the flat glass processing industry with 13 plants and commercial offices across the world. The company was established in 1941 as producer of mirror backing paints. Now the Group mirror paints are the most used paints worldwide and are daily applied in more than 70 countries in the five continents. This range of paints includes several versions, developed to best meet the most diverse needs of all mirror manufacturers. The product range is even more complete, now that the glass silvering array of products is available alongside mirror backing paints. Fenzi offers a unique set of products to cover the entire mirror production cycle.

The largest division of Fenzi is the insulating glass one. Fenzi produces the widest range of polysulphide, butyl, hot-melt and polyurethane sealants for high performance insulating glass, marketed worldwide by the Glass Alliance Network. This innovative alliance – made by the top-ranked industry leaders Fenzi, Alu Pro, Rolltech and Tecglass – has been created years ago to provide better service and complete solutions to glass industry professionals. Specifically Alu Pro and Rolltech are focused on developing latest-generation warm edge technologies widely used by the most important IG and architectural glass manufactures.

Fenzi produces also two different types of decorative paints for glass – enamels for screen-printing, enameling and satin-finishing glass, and organic paints for cold application - suited to all types of applications - architecture, interior design, home appliance, automotive, glass packaging. These range of enamels ensure the highest levels of performance and the utmost freedom of expression.

Fenzi commercializes worldwide also the most innovative machine and tools for digital printing on glass, developed by Tecglass, the company which became part of the Group in 2016. Companies and trade professionals interested in this particular kind of glass processing now have a perfect combination of services and products – machines, inks, tools, software - that meet the needs of designers and architects in terms of aesthetic results.

Whatever your field, Fenzi not only ensure high levels of performance (often the highest), but also the peace of mind that comes from the total reliability, durability over the time, ease-of-use and customer service designed to understand and meet the needs of those in the glass processing industry.

Products

If, for some strange reason, you have not yet had the chance to use them, you have certainly already seen them, starting with the many objects in your home: most of the mirrors in the world are made using Fenzi Duralux paints.

The Duralux range includes several versions, developed to best meet the most diverse needs of all mirror manufacturers across the world. You will find the perfect Duralux product to meet your needs, from the most traditional to sophisticated copper-free and zero-lead technologies.

The product range is even more complete, now that the Luxver glass silvering array of products is available alongside Duralux. Already the product of choice for some of the leading glass companies, with Duralux and Luxver, Fenzi offers a unique set of products to cover the entire mirror production cycle.

Thermoplastic and termosetting mirror-backing paints, available in copper-free formulations

Although each product has become a classic in its field of application, Fenzi research never stops; it strives to continually improve performance, and also to ensure practicality and ease-of-use, day after day.

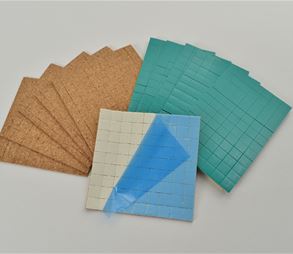

Along with several polysulphide, butyl, hot-melt and polyurethane sealants, Fenzi also supplies the manufacturers of IG units with spacer profiles in aluminum, steel, and stainless steel made at Alu-Pro and Rolltech facilities and sold around the world by the Glass Alliance network. Completing the product range are molecular sieves specifically engineered to absorb moisture vapor.

Two-component polysulphide sealant

One-part thermoplastic solvent free polyisobutylene based spacer

One component hot melt sealant

Two-component polyurethane sealant

Each of these numerous applications call for the highest levels of performance and the ability to ensure the utmost freedom of expression. Fenzi decorative glass paints are very popular in many markets, precisely because of their exemplary features. They are manufactured and sold in two different types: Tempver glass enamels for screen-printing, enameling and satin-finishing glass, and organic Decover paints for cold application to achieve maximum sheen and color. The Decover range includes the Glasslux, Sandolux, and Pearlux organic solvent paints, and the Aquaglass water-based paints.

Decorative enamels for screen-printing, enamelling and satin-finishing of glass.

On one hand, the coating must be able to stand up under conditions of enormous stress; on the other, they need to be as eco-friendly as possible. Fenzi met this big challenge by creating a dedicated division, Fenzi Solar Coatings, specialized in research applied to the innovative technologies for solar energy. The result is Duralux Solar Coatings, a range of solar mirror coatings engineered to meet the highest standards of durability and resistance required by the most advanced solar heating systems. Duralux Solar Coatings were so innovative in the chemical world the industry had to develop new reference parameters in order to test their performance.

A vast line of profiles for artistic (leaded) glass and a huge variety of architectural paints complete the range of products developed by the Group.

But that is not all. Fenzi can also provide a full assortment of flat glass processing accessories, like polishing wheels, glass cutters, small parts, hardware and machinery to support all phases of processing.

The Fenzi Buildcoat paints finish and protect architectural components for external use.

PROFILES FOR 'LEADED' ARTISTIC GLASS