Date: 16 December 2013

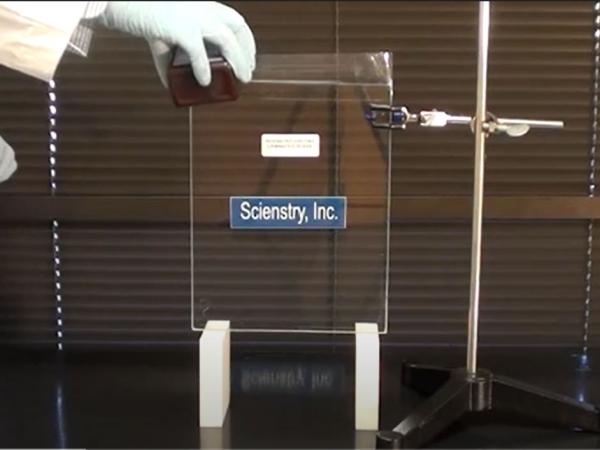

A novel but simple method has been invented to make a series of new products of casting laminated switchable glass TM (CLSG) with much better clarity, better strength and durability, better projection quality and very low cost.In comparison with traditional interlayer lamination, the overall cost for manufacturing CLSG is only 1/3, and labor and material costs are only10% excluding LC film. The manufacturing method is as simple as 1, 2, 3, that is, 1. Sandwich 3G Switchable Film TM with two pieces of glass and seal edges with tape, 2. Fill cavity with a special DayLightCure TM resin, 3. Place the filled panel in a bright area with natural light to cure the resin.

No special equipment is needed to make the casting laminated switchable glass. All processes are conducted in room temperature. Technically, anyone or any glass shop can make any size of casting laminated switchable glass in anyplace without any costly equipment. A mass production process is also developed for simultaneously making multiple panels with specially designed equipment. A series of CLSG products includes standard CLSG, hurricane proof CLSG and bulletproof CLSG made with same process but different DayLightCure resins.

All CLSG products are suitable for both indoor and outdoor applications, especially suitable for architectural applications. Architectural smart glass requires much better adhesion and durability for UV, moisture and temperature change. Older generations of liquid crystal smart film and smart glass cannot be used as architectural glass, because of weak adhesion between liquid crystal film and interlayer as well as instability for UV, moisture and heat. Several new window structures, including multi-layered structures with one layer of CLSG and one or two layers of glass and one or two air gaps, are also invented. The new structures are recognized by large US glass companies and famous architectural research institutes as new types of glass windows with best energy saving and projection capabilities.

The new production method and resins with a full UV filtration may be also used to produce regular casting laminated glass without 3G Switchable Film, click for video, and the regular casting laminated glass, hurricane proof glass and bulletproof glass have very low costs in comparison to traditional products. Please visit www.scienstry.us for more information with pictures and videos. CLSG may pay itself quickly by advertising and energy saving. This is a great opportunity to create or enlarge your glass and/or advertising business with very broad applications and huge market demands. This new technology is open for licensing.

600450

600450

Add new comment