Date: 9 January 2023

The volume of double and triple insulated glass is increasing and, as more units are produced at ever increasing speed and cost pressure, with the corresponding amount of waste, the number of insulated glass panes needing to be replaced at the end of their service lives is also increasing. In the best-case scenario, these panes find their way to a recycling specialist, who will shred them and process them for reuse. Thus far, however, only a fraction has found its way back to the flat glass tank furnace, thereby completing the material cycle of valuable resources.

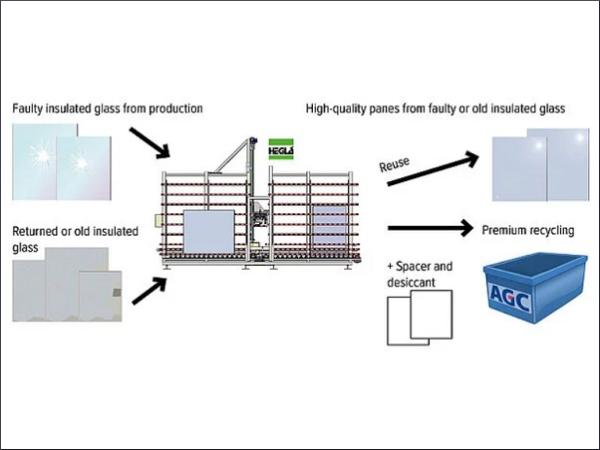

‘In view of the increases in energy and raw glass prices and the apparent need for high-quality fragments for flat glass production, we began to think about how to gain value from end-of-life or faulty insulated glass’, explains Dr Markus Schoisswohl, Managing Director at HEGLA New Technology. To take a holistic view of the value stream, HEGLA and AGC have joined forces in a development partnership, which will see AGC focus on the supply chain while HEGLA will be responsible for the development of machine technology.

The first stage is IG2Pieces, a machine that allows insulated glass elements to be separated whilst preserving the size of the glass. To do this, the machine cuts around the edges of the insulated glass, allowing the largely intact panes to be separated from the frame. These separated fractions have greater value than insulated glass units that have been discarded without being separated. ‘We decided to partner with HEGLA in this cooperation as we were looking for additional, high-quality fragments to feed into our flat glass tank furnaces’, explains Geoffroy van der Rest, Project Lead at AGC.

Increased demand for reuse and circular economy

‘For the production of panes alone, there was no reason to preserve the glass intact’, explains Dr Markus Schoisswohl. ‘Our vision was also to establish a seamless separation process, where panes of incorrectly produced or faulty insulated glass could be reused in new insulated glass elements.’ Manual separation of insulated glass requires manual dexterity and is a time-consuming process, so it tends to be used only for elements with high added value. ‘IG2Pieces makes it economical, especially considering increasing raw glass prices, with the added benefit of improved separation quality’, explains Dr Markus Schoisswohl of HEGLA New Technology.

In addition, the machine also contributes to increased demand for circularity in terms of reuse. Panes are separated from end-of-life insulated glass and reprocessed, so that they can be prepared for a new lease of life. ‘Circularity and built-in CO2 in buildings are becoming increasingly important for project developers and architects’, explains AGC Project Lead Geoffroy van der Rest. ‘We regard this concept as the basis for circularity in different modes – fragments for recycling and panes for reuse.’ AGC and HEGLA are looking forward to the months ahead, during which the machine will be thoroughly tested and analysed within the value stream.

‘With IG2Pieces as a starting point, we are committed to responsible development of flat glass processing. We are grateful for the collaboration with AGC, which allows us to not only offer machine solutions, but to give our customers a direct buyer for the ensuing product as well’, explains Bernhard Hötger, CEO of HEGLA.

600450

600450

Add new comment