Date: 18 September 2019

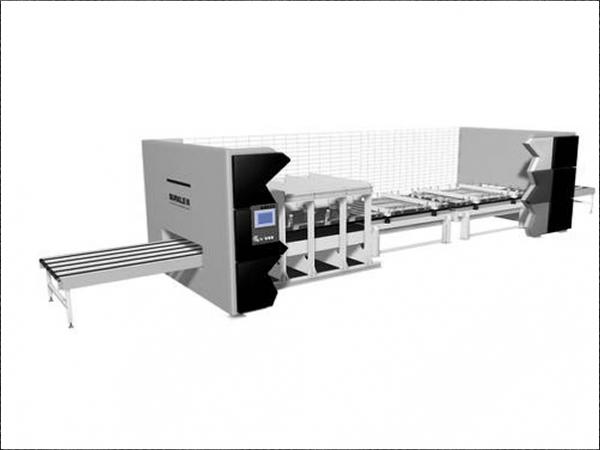

The Bürkle IFL process is a multi-stage laminating process, which uses a vacuum flat press heated on both sides in the first step. For glass thicker than average, a second step is recommended, which uses a flat press that also applies heat from above and below to the product. A flat press with cooled press plates is then used to cool the laminated glass. The system has a useful lamination area of 2,6m x 5,0m.

“This serial production system provides significantly faster turnaround time and reduced energy cost compared to conventional autoclave systems with unrivaled uniform glass laminate thickness. The system also uses a streamlined lamination process, which will further improve our process efficiency in laminating glass for our current product portfolio,” says Bruce Wesner, Sr. Director of Engineering Services, at PGT Innovations.

Bürkle’s in-line flat lamination system is ideally designed for production of laminated glass, safety glass (VSG), smart glass, decorative glass, solar modules, and other specialized glass products.

The Bürkle IFL process (IFL=Inline Flat Lamination) is distinguished by:

- Particularly fast lamination of laminated glass compared to autoclave processes (reduction of lamination costs)

- The possibility of line integration of the machines (inline process)

- Highest laminating quality due to particularly homogeneous heating plates heated on both sides

- The possibility of lamination with low pressures

- Much lower energy consumption compared to the autoclave process

About PGT Innovations: PGT Innovations manufactures and supplies premium windows and doors. Their highly-engineered and technically-advanced products can withstand some of the toughest weather conditions on earth and are revolutionizing the way people live by unifying indoor and outdoor living spaces. For additional information, visit www.pgtinnovations.com.

About Bürkle: Bürkle is one of the technology and world market leaders in the field of press, laminating and coating technology. The headquarters of the company, founded in 1920, is located in Freudenstadt in the northern Black Forest. With approx. 500 employees, Robert Bürkle GmbH presents itself as a modern, future-oriented company that supplies highly complex high-tech press and coating systems for the furniture, plastic card, printed circuit board, glass and photovoltaic industries.

The Bürkle IFL process will be exhibited at this year's Glass Built USA from September 17th – 19th, 2019 at the booth of Bürkle North America, booth no. 1351.

600450

600450

Add new comment