Date: 30 January 2018

Structured thin or ultra-thin glass wafers are used as a substrate for sensors, batteries, and diagnostic technology. The breakthrough will enable new applications and further miniaturization of electronics through thinner glass wafers and structures that are more precise. The technology offers the lowest structuring radius of just 150 micrometers (μm) and a feature size tolerance lower than ± 25 μm.

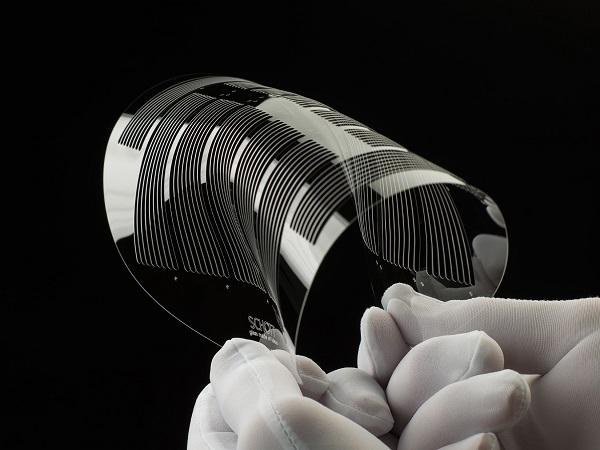

International technology group SCHOTT has developed a unique process that enables freedom of design and high precision in structured glass wafers. SCHOTT will highlight its new FLEXINITY™ portfolio of structured glass solutions at booth 1207 at Photonics West in San Francisco from January 27 to February 1.

“Component manufacturers have been on the hunt for more precise, lighter, and thinner structured glass wafers, but mechanical structuring methods have reached their limits,” said Matthias Jotz, Product Manager at SCHOTT Advanced Optics. “New applications that have been waiting for smaller components are finally possible.”

Meeting tomorrow’s demands – today

An increasing trend toward miniaturization in IC packaging, biochips, sensors, micro-batteries, and diagnostic technology has pushed demand for high-precision structured glass wafers, even as technology to create them has reached its limits. This has made it difficult to shrink wafers any further, and limited the pace of innovation.

SCHOTT’s new FLEXINITY™ structuring portfolio offers complete freedom of design on glass wafers and thin glass. With FLEXINITY™, any shape is possible, and the process allows extremely tight tolerances and structures.

Structured wafers are available made of glass types from SCHOTT’s unique down-draw glass portfolio, or plano-plano-processed BOROFLOAT 33® borosilicate glass.

Various glass types and thicknesses: freedom of choice

SCHOTT’s structured glass wafers are available in 4-inch to 12-inch wafers, in thinness ranging from 0.1 to 3.0 mm. The smallest structuring radius is set to 150 μm and the feature size tolerance is lower than ± 25 μm.

Customers can choose from several different glass types, such as borosilicate glass (MEMpax®, D 263® family, BOROFLOAT 33®) and alkali-free glass (AF 32® eco).

The breakthrough technology gives manufacturers in different industries the ability to meet the challenging demands of the future, starting today.

SCHOTT has already created sampling capabilities; mass production will be ready 2019.

600450

600450

Add new comment