Date: 26 October 2017

An analysis of these data helps to optimize production processes and to proactively plan maintenance tasks. This allows cost reductions, increased machine availability and improved productivity.

The eluCloud captures machine and production data during active operations. This data is combined to form meaningful analysis results and are provided in real time.

Consequently, what is currently taking place in production and what has already been accomplished can be viewed at any time from anywhere. In this way, the eluCloud enables responsible parties to quickly recognize deviations from the desired production flow.

The live display of the current machine status and the real-time calculation of momentary machine efficiency are among the features which provide assistance here.

Problems in production become apparent very quickly as a result and the data collected help in structured troubleshooting and analysis. Moreover, the eluCloud offers an overview of currently running jobs as well as detailed information on the parts produced.

This information provides the basis for exact analysis of production times and individual optimizations. The eluCloud product group also helps in demonstrating to potential clients: "We are a reliable and technologically advanced partner."

Industry 4.0 - decision-relevant information for long-term success, everywhere and at all times

Machine data acquisition has a long tradition. Often times, the data was only available directly at the machine. Consequently,the data had to be manually exported from the machine or perhaps even recorded by hand in writing.

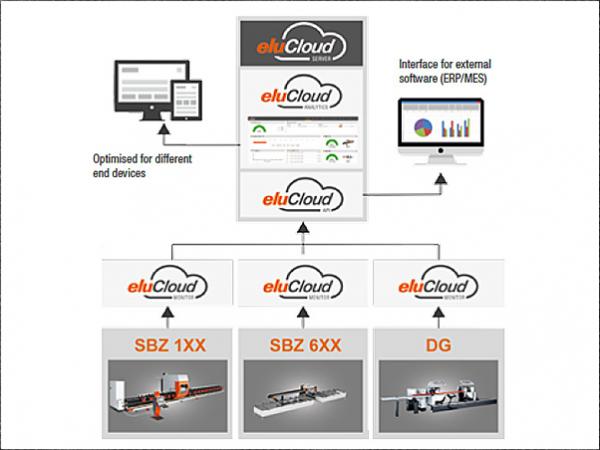

Our new product group is called "eluCloud" because the machine data are now digitalized and transmitted to the central eluCloud server fully automatically during active production operations.

Gathering the data long-term on a central server makes sense because large amounts of data are acquired and this approach avoids burdening the machine PCs with the task of storing it locally.

Of foremost importance for elumatec and elusoft is the protection of the acquired data. This is why the eluCloud solution differs from other well-known cloud products. The eluCloud server was specially developed so that it can be integrated into a company's existing IT infrastructure with no great effort.

This means that the data remain safely within the company. The requirements of Industry 4.0 are met by the eluCloud with the help of various different modules which offer individualized options for accessing the saved data, analysing them, or integrating them in existing applications. This ensures that the data are always available where they are needed and can thereby contribute to long-term success.

The eluCloud product group

The eluCloud product group comprises four different modules and one app which makes the eluCloud functions accessible worldwide from a smartphone, tablet, laptop or PC. With this app, the user can check up on the status of machines operating in the plant back home with a smartphone while travelling.

The eluCloud product group comprises four different modules and one app which makes the eluCloud functions accessible worldwide from a smartphone, tablet, laptop or PC. With this app, the user can check up on the status of machines operating in the plant back home with a smartphone while travelling.

For business travellers, the app is like a pair of binoculars which allow developments at home to be recognized in advance. Being well-informed, it is possible to react quickly if deviations from planned schedules arise. The four eluCloud modules are called eluCloud Monitor, eluCloud Server, eluCloud Analytics and eluCloud API.

eluCloud Monitor

The eluCloud Monitor is the machine's digital window. This module processes the recorded machine and production data and presents them in a clear overview.

This makes the eluCloud Monitor the fundamental building block in the overall eluCloud solution. The designation is clearly derived from the verb "to monitor." The modern controllers of elumatec machines are able to capture many types of data for this purpose in real time, which you can then access with the eluCloud Monitor.

For instance, this includes information about the quantities of parts produced, error messages, or detailed time protocols concerning downtimes, production duration, spindle operating times or the service lives of the tools used.

This exact time information helps in recognizing the necessary maintenance intervals in advance, allowing better planning for them.

eluCloud Server

All of the data from the linked machine go onto the eluCloud Server. It stores all status messages and makes them available for analysis and utilization. The eluCloud server was specially developed to be integrated into a company's existing IT infrastructure.

Provided that there is free server hardware capacity in the company, the eluCloud Server can be installed on existing systems with ease. The eluCloud Monitor module and the eluCloud Server form the basic equipment for customers who wish to use the eluCloud.

The solution provided by this combination allows important key figures such as operating hours, spindle operating times or the quantity of processed parts for an individual machine or an entire machine pool to be monitored. In fact, it is irrelevant whether all of the machines are operated at the same location or are distributed across several production sites.

The data are prepared and presented in the form of a web page and can be viewed from any end device with a connection to the eluCloud Server. The dashboard gives an overview of each individual item of information so that it can be seen at a glance.

eluCloud Analytics

eluCloud Analytics is a supplemental module for subsequent analysis of product and machine data. This makes detailed analysis of topics such as the following possible: production utilization, progress of job processing, processing times for jobs, analysis of individual machines, analysis of the entire machine pool or processing times for individual parts.

eluCloud Analytics, with the processed information and its user-friendly filter options, also supports the optimization of production times, for example.

Through the capture and analysis of non-productive times such as clamp positioning operations, tool changes or part orientation changes, the techniques employed in production can be refined and the times can be reduced in a sustainable manner. The module also helps in troubleshooting and product costing analysis.

Using filter functions allows exact determination of the required production times for a job or a part. This knowledge also serves as a very good basis for the costing of future jobs. Using this information as a basis also allows questions such as, "When did which downtimes occur?" and "What was the reason for this?" can be answered easily after the fact.

eluCloud API

A core characteristic of every Industry 4.0 solution is the seamless communication between individual machines or between the machine and the software, which is often summarized with the term "Internet of Things." This can be implemented with the help of eluCloud API.

The term "API" refers to an interface with which the eluCloud solution can be integrated into existing Industry 4.0 concepts as well as linked to other software solutions.

The machine data and analysis results which are gathered in the eluCloud can be accessed and further processed for this purpose by external programs, such as cost accounting programs and ERP or MES systems.

For instance, it would also be possible to automatically send messages to an internal ordering system when the eluCloud system has recognized that the maximum service life of a tool in use will soon be reached.

600450

600450

Add new comment