Date: 3 October 2018

Bostik, a leading global adhesive specialist for industrial, construction and consumer markets, is proud to announce the launch of Bostik 6000, a next generation hot melt sealant for insulating glass units (IGUs), at Glasstec in Düsseldorf, Germany October 23-26, 2018.

Formulated with exclusive i-BoostTM technology, Bostik 6000 is an active single-part hot melt sealant that offers enhanced performance, productivity and durability over existing best-in-class IGU sealant options.

“By understanding the insulating glass market needs for more sustainable solutions, Bostik saw an opportunity to develop an innovative sealant that combines enhanced durability with improved productivity and safety for manufacturers,” said Olivier Bousquet, Business Development Manager for Bostik’s Building Components market.

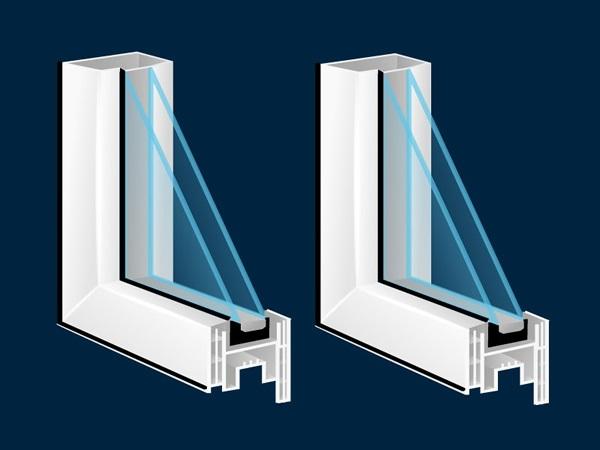

With higher thermal resistance and tensile strength, Bostik 6000 is well-equipped to handle continual application stresses, allowing manufacturers to meet increasing demands and regulations. Easy to use, this product allows to reach unprecedented speeds on automated lines (while still compatible with manual application), with no curing time, the shortest skinning time on the market, and no waste. It also is a versatile sealing solution that exhibits excellent adhesion to glass and commonly encountered surfaces in IGU construction.

With this new product, Bostik confirms its technical leadership on insulating glass sealants and the value of the single part butyl hot melt technology over traditional bi-component technologies, such as polyurethanes and polysulfides, allowing boosted performance, productivity and durability as well as a better HSE profile.

Interested in understanding how Bostik 6000 can boost your operations and products? Visit www.bostik.com, or stop by Glasstec, Hall 17 – Stand A60.

600450

600450

Add new comment