Date: 2 October 2018

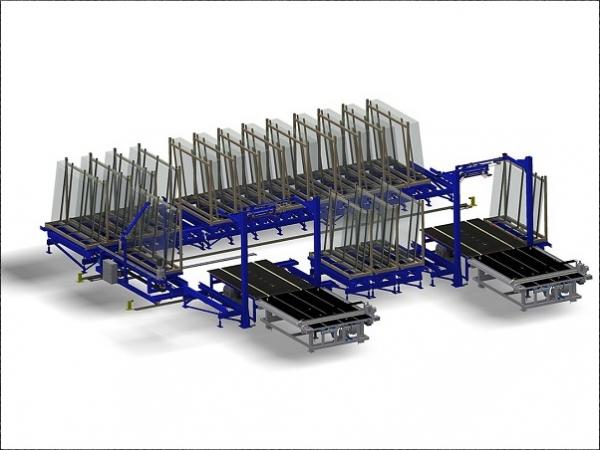

OptiLoad is an automated glass-handling and storage system that enables manufacturers to manage more glass SKUs in less factory floor space while increasing capacity, efficiency, yields and safety. One OptiLoad system can serve multiple cutting tables without any table having to wait for the next glass to arrive when the current pattern is cut.

OptiLoad is the second IAS system to earn the award. In 2011, the original OptiGas 500 tunable gas filling system with verification earned most innovative machine. The updated version is OptiGas II.

“The Optiload system is impressive because of the sheer scale and versatility of it,” one judge noted. “Smaller and similar glass handling systems have been built before, with limited success, so it is great to see that this team has figured out a viable solution.”

Benefits of the OptiLoad system include serving all glass to multiple cutting stations from one inventory, increasing capacity by eliminating waiting at cutting tables, storing more glass in less space, higher yields by having at hand multiple sizes of the same SKU, the ability to handle any package size and type and reducing damage and improving safety by eliminating manual labor pushing carts.

“Every year, we receive nearly 100 entries of products and processes that remind us of the true innovative spirit of the industry,” says Emily Thompson, editor in chief, Window & Door magazine. “The winning entries present creative solutions to the industry’s challenges and portray the next evolution of fenestration trends.”

“Automated raw glass storage and handling systems are the fastest growing business for us,” said Ryan McHugh, vice president of sales at IAS. “OptiLoad is generating an increasing number of large orders as companies better understand the proven benefits.”

“We have new orders and customers returning for multiple units based on the much higher efficiency, increased yields and space savings they gained with their first OptiLoad systems,” said McHugh. Each system is customized from the shuttle, turntable, double-sided loader, picker and tables in the product line.

“This year’s award recipients stood out to a well-respected panel of judges who have decades of experience in the industry,” said Thompson. “Congratulations to the 2018 Crystal Achievement Award honorees.”

IAS began business eight years ago with the OptiGas advanced integrated gas filling and testing system. In addition to glass handling and edge deletion, the company now offers a comprehensive lineup of gas filling and testing systems including a robotic gas filling with automated fourth-corner patching.

“Companies buy our products because we help them reduce costs, eliminate bottlenecks, increase capabilities and improve quality in glass fabrication,” said McHugh. “With our automated solutions, you can significantly upgrade raw glass handling and storage, fill and verify IG gas content faster than your production and move glass from the oven to the sashline without touching it.”

Product names include OptiLoad, OptiClose, FastGas, Edge Deletion System, ThermalCHECK, TurboFILL, OptiCooland TemperCHECK.

600450

600450

Add new comment