Date: 8 October 2018

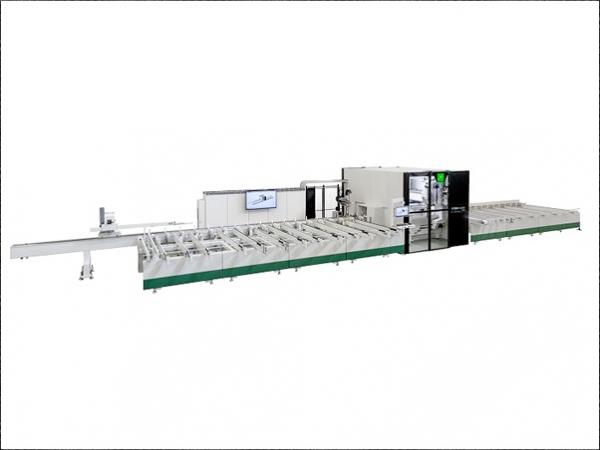

The fruit of two years of experience in the R&D department of FOM INDUSTRIE, located in the Italian town of Cattolica, the new fully automated LMX650 line manages to produce machined parts cut to custom sizes through a multi-spindle machining center and a cutter with movements on 4 axes controlled, offering maximum versatility in numerous applications of machining and cutting of aluminum profiles.

Depending on the configuration, the installation can have up to 50 motorized axes controlled by CNC. The extremely careful design, evident in the structure of the soundproof cabin that is positioned in the center of the line, as well as the optimization of the features, are the highlights of this top product of Fom Industrie range.

The labeling of bars in movement, jaw plans before and after the electrospindle unit, and the blowing system incorporated onto the work table are just some of the peculiarities that favor the speed and precision of production of this line that already has six patents in in the works.

The multi-spindle machining unit facilitates the execution of several machining operations on all four sides of the aluminum profile. Likewise, it allows oblique machining by oscillating mandrels with pneumatic or continuous orientation with controlled axis.

The machine can contain up to 18 electro-spindles, whose positioning must be verified according to the necessary machining. Its placement on the tile is studied in each case to adapt the operation to the needs of the user, such as, for example, oscillating electro-spindles for oblique machining.

LMX650 is enabled with the system LOLA (Log On Live Automation) Fom Industrie contribution of the Internet of Things (IoT). It is a Cloud service to monitor the productivity of the ‘Industry 4.0 ready’ machines from Fom Industrie.

Thanks to certain sensors installed in the machines, LOLA receives statistical data in real time about the state of the installation and the progression of the orders, which, in turn, facilitate other analyses for the end user. The ‘digital factory’ is already a reality and Fom Industrie proposes a tool in line with the current trends of optimization and integration of production processes, the main goal of which is predictive maintenance.

10D18

600450

600450

Add new comment