Why tempered glass washing matters

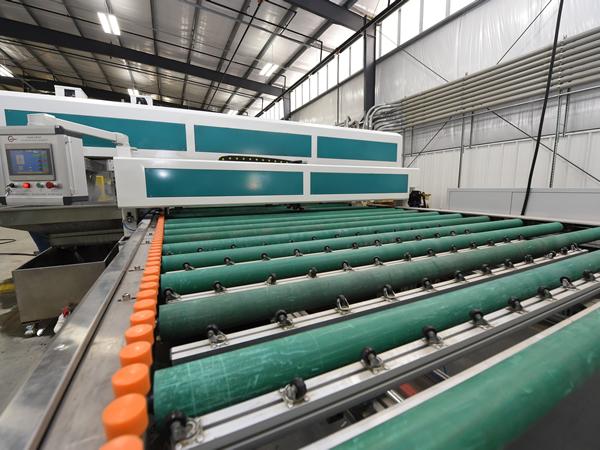

Though the glass tempering process itself is very important to meeting the specifications of the finished product, as important (or maybe even more so) is pre-processing glass before it goes into the furnace. This pre-processing includes cutting, edging and glass washing.

Washing the glass after cutting, edging and handling cleans the glass of any debris, dust and glass chips that may still be on the surface of the glass. If there is any surface protection on the glass, such as coatings to enable safe handling or protect it from damage, washing can also remove these and any resulting residue.

Tempered glass washing benefits

The benefits of removing these impurities before the glass enters the furnace are twofold. First, any dirt or glass dust that’s on the glass can damage the glass during the tempering process, leaving scratches, pockmarks and dents in the glass.

While debris may not be visible directly after tempering, little bits of dust and glass chips adhered to the glass can be dislodged during later cleaning methods (window washing, scraping) leaving scratches across the glass.

Second, washing glass early in the glass tempering process also keeps these impurities out of your furnaces. Once inside a furnace, these impurities adhere to ceramic rollers, leaving them to not only attach themselves to later pieces of glass coming through, but also increasing wear and shortening the rollers’ lifespan.

Increased quality, reduced waste and loss of glass all lead to increased efficiency and savings. These are the reasons you should always wash your glass before the glass tempering process continues.

Glass washing best practices

Here are some tips to help your glass washing be as effective as it can be.

- Use demineralized or deionized water. With no minerals in the water, there are no minerals to be deposited on the glass.

- Never use detergent. Detergent can cause marking and increase furnace rolls deterioration.

- Use soft brushes to avoid scraping impurities across the glass. These brushes should run against the path of glass travel so particles are brushed back, away from the clean glass. If the brushes can’t all be set to go backward, at the very least the first brush on both the top and bottom should go backward.

- Keep the glass moving to minimize the time the clean glass takes to reach the furnace, reducing the chance of new particles adhering to the glass. Also, stopping glass in the washer will cause marks on coatings.

- Make sure the glass is clean, dry and free of residue before it enters the furnace.

- Perform regular maintenance to ensure the machines are working properly.

- Clean washer to manufacturer spec prior to use.

Add a glass washer to your tempering line with help from HHH Tempering Resources

To improve the quality of your glass product and increase your tempering line’s efficiency, check out our selection of glass washers, all backed 24/7 technical service and support from our tempering experts. Or if you’d like a quote, contact us at sales@hhhtempering.com.