According to Gilbert Rancoule, development of SO2 injection is creating singular working conditions that influence roll operation and require understanding of the chemical reactions created.

In the process of thermal toughening, the glass is heated to a temperature just below the softening point and is then quenched rapidly in air. The outside of the glass cools rapidly, while the inside contracts and cools more slowly. When the glass eventually reaches a uniform temperature, a compressive stress will have been set up in the surface and a compensating internal tensile stress will have been developed.

The surface compressive stress actual values depend on such factors as glass thickness and heat transfer coefficient, as well as the heat treatment schedule. Limiting external factors that could modify the quality of the glass surface has always been the goal of the industry, as well as allowing for process flexibility.

The reaction between Na ions and injected SO2 is creating a sulphate surface on the glass surface that is stable under normal working conditions. During handling of the glass sheet, the sodium sulphate powder is transferred to the glass sheet environment.

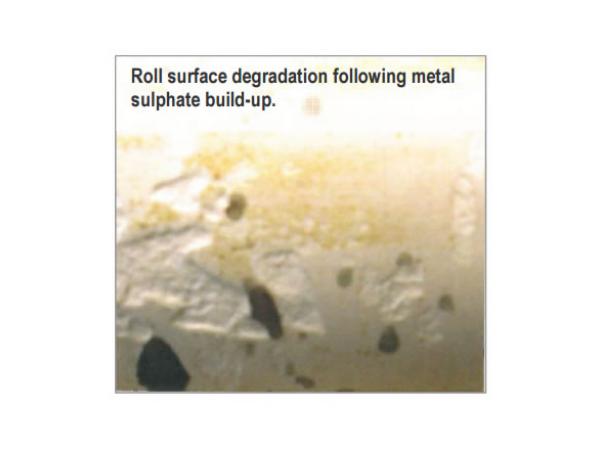

Roll surface degradation following metal sulphate build-up.

A deposit of sulphate is observed at the interface of glass and conveyor rolls, which is considered of potential benefit for the contact surface longevity. In effect, the sodium sulphate is slowly evolving in a continuous interface of neutral reactivity towards the glass chemistry. The continuous gaseous interaction is conducting to the creation of a solid lubricant Na2SO4, stable at temperatures that are standard practice for glass heat treatments; tempering or annealing zones.

The yield of Na2SO4 formation is linked directly to the moisture level, concentration and temperature; if the action of sodium sulphate is well known, some products of reaction could present some negative aspects in the glass contact quality, mainly in the low temperature transient domain. Metastable forms of sodium sulphate could be generated as a function of the environmental conditions and lead to complex reactions that may induce unexpected results in the function of temperature.

Unstable sodium sulphate species could form and interact with the furnace environment and the glass to capture particles and dust that may create glass defects if corrective actions are not taken to avoid undesirable operating conditions. Glass quality and ZYAROCK® roll efficiency are enhanced by observing furnace adjustments.

GLASS DEFECT MODES

Observation of the glass surface gives a high level of information about the furnace working environment and operating conditions. Furnace degradation over time and temperature lead to quality impacts that will be seen either in the furnace or the glass. Furnace maintenance is key to glass quality but we could also analyse the evolution of the glass requirement as a function of the most demanding applications.

The relationship between effective glass cleaning procedures, furnace and factory cleanliness, maintenance conditions and glass surface quality is certainly a recurrent investigation that needs to take place when the operation is analysed-

(1) Glass deposit; (2) Mechanical indentation; (3) Paint deposit

Good fused silica roller surfaces are maintained through strict control of the working environment to avoid damaging the contact surface. Important rules should be observed to avoid sodium contamination linked not only to roll handling, transfer and cleaning but also to glass preparation prior to tempering.

When roll cleanliness is achieved, the next step should be to avoid the introduction of particles inside the furnace through dust generation and air flow control before moving to furnace thermal consistency.

Sodium sulphate stability function of temperature and atmosphere relative humidity.

Click to enlarge

UserFiles/Picture5.jpg

.jpg)

Thermodynamic analysis of the sodium sulphate system – Na-O-S phase stability diagram at 300.000°C.

Click to enlarge

UserFiles/Picture7(2).jpg

.jpg)

Thermodynamic equilibrium for glass chemistry under SO2 vapour environment.

Click to enlarge

UserFiles/Picture8(1).jpg

THERMAL PROFILE AND GLASS INTERACTION

The quality of thermal consistency in the furnace determines not only the speed of heat transfer from the furnace environment to the glass but also the relative physical stability of the glass sheet during transfer in the furnace. The glass type and chemistry, as well as glass thickness should be taken into account to define the best operating conditions at the furnace entrance.

The temperature of the rolls and the furnace entrance thermal flow are key working parameters that are defined to ensure the best homogeneity on top and bottom glass surfaces. The minimum deformation of the glass sheet should be considered through the adaptation of heat flow in the initial phase of the heating profile:

- Glass heat absorption (thickness, chemistry, coating, texture).

- Bottom/upper temperature gradient (static or turbulent heat flow, convection mode, roll type).

- Reflective heat transfer (refractories).

- Furnace design to glass tempering type (engineering and heat control).

- Glass edge effect.

Glass geometric stability is linked directly to the thermal profile as glass thermal expansion depends on glass conductivity and IR absorption. A difficult equilibrium is achieved on the edge of the glass sheet, where higher heat transfer is obtained due to the convection and radiative heat conduction.

Insulation quality is a primary objective when considering the working environment of the furnace, as it is often linked to dust generation fibres or particles (when not involving chemical changes when looking for potential reaction with the furnace atmosphere).

Degradation of the lining is also a question of time and temperature. Consistency of the rolls’ seals is an important parameter for achieving maximum thermal stability and reducing the dust coming from the mechanical wear and heat leak. The perfect insulation prevents overheating the roller end cap, thus inducing shipping and hot TIR problems.

ATMOSPHERE AND GAS INTERACTION

Influencing parameters are keys for the understanding of sodium sulphate stability. If we consider that the formation of sodium sulphate is a real advantage for the application, it is important to understand how modification of the environment and concentration will impact the formation of Na2SO4.

Different parameters for the formation of Na2SO4 include the collective influence of moisture, low temperature treatment, high concentration SO2, glass chemistry interaction and roll conditioning.

MOISTURE AND LOW TEMPERATURE

Moisture will directly impact the stability of SO2 inside the furnace, while the dual action of temperature and moisture will directly impact the concentration of SO2. When humidity (moisture 10% maximum water in air) is mixed to the SO2 inside the furnace, sodium sulphate hydroxyl is formed in the low temperature zone. This can lead to the creation of a metastable Na2S2O7 phase in the medium temperature range before dissociation to Na2SO4 at higher temperature.

On a same reaction, the potential formation of sulphuric acid can be seen in the low temperature zone, coinciding with the change of hydroxyl.

SO2 CONCENTRATION

Low concentrations in SO2 and high temperature operations are necessary to reduce the conversion to higher oxidation state sodium sulphate. Only stable at the low end temperature range, sodium bisphate has a viscous behaviour that creates the conditions for adhering oxides and metals from the working environment to the glass and to the rolls.

The presence of moisture at the same time as high sulphur concentration in the atmosphere is the most undesirable configuration for the stability of the sulphate phase. The formation of Na2SO4 should be the priority over other sodium phases to ensure a clean operation.

GLASS CHEMISTRY INTERACTION

Sodium vapours in the furnace are clearly dependant on the temperature and glass chemistry. It is recommended to control furnace atmosphere distribution and gas flow through SO2 diffusion and the thermal gradient generated in the furnace to achieve stable operating conditions for the formation of Na2SO4.

Elements from the glass also have reactivity with SO2 but it can be verified that stability of the different sulphates is possible at high temperature. This reactivity is difficult to obtain inside the glass, however, due to the stability of the ionic species compared to the mobility of the sodium ions.

The most prevalent reaction should consider free metallic elements present in the furnace as dust generated either by the furnace containment walls or by low temperature condensation zone reactions, involving sulphur and moisture exchanges.

The ceramic roll does not create a condition for build-up and should be considered a neutral surface under most conditions. High temperature and stable atmospheric conditions are only partial situations to explain clean operation and should never replace furnace maintenance routines.

When considering a metallic roll in the SO2 environment, numerous reactions are possible that introduce metal instability at high temperature and the creation of sulphur phases of the metallic species (Fe, Ni). If moisture is involved, the reactivity of the roll increases exponentially due to the corrosive attack of the metal.

The presence of sodium on the surface of a fused silica ceramic roll is without negative effect for the ceramic if the chemistry of sodium sulphate is realised. However, when the operating environment creates the conditions for metastable sodium sulphates, hydrogen sulphur, bisulphate or sodium oxide, we have all the elements for a slow ceramic surface reaction that involves physical degradation.

The crystalline transformation of the fused silica induces irreversible surface damage on the roll and should be prevented at the initial stage of the line service through good maintenance of the rolls, designed to clean the ceramic surface from sodium oxide. Observation of the roll is achieved by removing unexpected build-up when deposits other than sodium sulphate are noticed.

Dust and oxide build-up on the rolls need to be removed before they become strongly attached inside the reactive sodium oxide. Such operations are performed by clear water cleaning outside the furnace, as many times as necessary to stabilise the ceramic surface chemistry and return to nominal roll conditioning.

CONCLUSION

Glass quality is linked to the cleanliness of the furnace environment. Dust control is obtained through good insulation characteristics, with roller seals and air flow introduced to the furnace. The thermal consistency of the tempering environment links the glass properties to furnace capability and the product flexibility requirement.

When operating conditions are optimised, the introduction of SO2 in the furnace gives the final touch of contact characteristic with the formation of sodium sulphate interlayer to avoid extreme conditions from glass dimension and type.

Strict control of atmosphere confinement and gas flow in the furnace should be conducted to avoid the formation of high oxidation levels for the sulphate, which could lead to viscous liquids and create service problems in the transition stage of the operation.

The furnace environment is to be considered with secondary reactions involving dust and particles from the lining, oxide-reduction and corrosion that are prejudicial to glass quality in normal operating conditions.

Author: Gilbert Rancoule, Director- R&D Vesuvius Fused Silica Division

The article was published for the first time in GLASS WORLDWIDE MAGAZINE- JULY/AUGUST 2011

Source: www.vesuvius.com/fileadmin/user_upload/Glass_handling_in_tempering_furnace.pdf