Warehouse stocks of passenger car windscreens do not need replenishing; furthermore, the weak automotive replacement glass (ARG) market, along with decreasing OEM orders, are not offering enough demand to keep larger production lines in operation. The recession has caused a decrease in the demand of personal vehicles, growing demand for public transportation. Also the need for special vehicles which are used to harvest crops and manage forests has remained steady. These factors ensure the relative stability of this segment of the safety glass market.

A brief review of bus and special vehicle windscreen manufacturing techniques will show that, despite the continuing need for the glass products, the industry’s production technology has not been significantly improved in a decade. There are considerable opportunities to advance the state of the art.

Production Technology

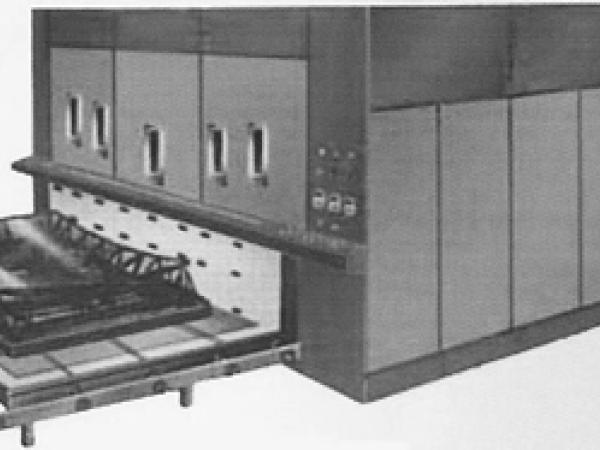

Gravity bending is the only available method for larger, complex, bus and special vehicle windscreen manufacturing. It is amazing, that heat is the most important factor producing these windscreens efficiently, but the technology is still infact very undeveloped. Today these windscreens are produced mainly in infrared-radiation-heated single-chamber and serial furnaces. In the past, furnaces were equipped with longer heating elements controlled in single rows; currently, the heating element rows are divided into three or even six individually controllable parts which enable more accurate heating. The first automatic serial furnaces were introduced in the 1980s. The furnaces produced in the new millennium are highly automated, featuring temperature-controlled bending with multiple pyrometers, heat balancing, adjustable heating elements and power rates, bottom heating, temperature-controlled glass support, and mold/glass movement controls. Most of these technical features were invented before 2000.

Automation of basic furnace functions frees the operators to concentrate on glass loading and other tasks. It also improves efficiency by reducing the work force and decreasing human errors that might affect yield. For example, modern furnaces include a glass center support system, probably introduced during the 1970s, that replaced an outmoded “aluminium stick” system built into the mold. The newer support system is mounted into the mold wagons to reduce pre-bending breakage. Originally manually controlled, the support system’s movement is now determined by the user interface temperature-based settings. Automation allows the operator to control the glass bending according to visual observation; the glass wing can be bend to into its final form only after it reaches the optimal temperature. Bending with automated controls is probably the only viable method for forming complex bus and special vehicle windscreens without any external manipulation.

.jpg)

Furnace Characteristics

Single-chamber furnaces remain the most common manufacturing units for several reasons. Investment costs are low compared to those for serial furnaces; one-hour cycles accommodate short production series with frequent mold changes; construction facilitates multiple views into the heating chambers and improves ergonomics for operators who can work from a standing position; and simple construction and mechanics guarantee reliable operation. However, single-chamber furnaces definitely have drawbacks. For example, production capacity is small; on average, these furnaces produce only five to eight parts per eight-hour shift. To facilitate greater production capacity, several single-chamber furnaces must be utilized, requiring extensive floor space. In contrast, serial furnaces require less floor while offering similar production capacity than multiple single-chamber furnaces. Single-chamber furnaces are also not energy-efficient. The heating elements require the same amount of energy for each production cycle, while the hot air released by the cooling process is wasted. Compared to single-chamber furnaces, serial furnaces are much more energy efficient since the lower track’s cooling energy can be harnessed to heat the glass on the upper heating track and also the heat mass left into the chamber can be utilized, in continuos serial production.

Both single-chamber and serial furnaces are produced with open and closed wagons. In the single-chamber furnaces, a closed wagon provides the option of pre-heating, assuming a special preheating section is available. This enables shorter cycle times because while the bending chamber is busy, the loaded wagon can be preheated. The disadvantage of a closed wagon is that it often limits working space for loading, unloading, mold tuning, and maintenance during operations. In contrast, an open wagon allows free access to the wagon platform during the loading actions. The windscreen cooling rate is sometimes faster with an open wagon. Due to its construction, an open wagon can also perform better from the windscreens edge compression qualities, since the glass edges are exposed to cold air flow immediately after the final bending. This air flow coming from the bottom of the glass can eliminate possible delamination problems.

.jpg)

Production Problems

Although furnaces in use today are equipped with modern automation, the process-related problems associated with the older, fully manual furnaces persist. For example, variation in the final product is unavoidable, especially with larger windscreens, since repeatability depends completely on operator actions. The final bending of the large windscreens is still handled manually by an operator controlling the furnace with the user interface. It is very difficult to reproduce the same center sag and edge size when these are estimated visually from a distance and with a limited view into the furnace. Glass temperature can be used only as a reference, since the bending conditions still vary.

Another enduring processing issue involves the practice of “sticking” as a way to externally manipulate the glass into its final shape. This method leaves marks that appear as dips, black stripes and lines in the inner surfaces of the windscreens. “Sticking” method enables production of more complex shapes with simple mould tooling and furnace technology and amazingly is in common use by leading European manufacturers. A while a go other manufacturers were simply not able to produce large complex shapes, but this is now changing. New companies in the industry are not using such a method, instead they are determined to produce all the glasses with out any external manipulation. This means careful employment of all the up to date furnace systems and superior mould technology.

Development Opportunities

Future development should advance the state of the art by improving process controls and making the process further automated leaving only the loading, minor process supervision, process fine tuning, and unloading to the operators. Further research should be conducted with the goals of ensuring energy efficiency, increasing output capacity, improving quality, and addressing ergonomics issues. Windscreen manufacturers’ internal research has led to innovations in mold construction and tooling, process controls, and glass shaping, making it possible to develop and produce the windscreen for the vehicles available today. Recently, some interesting trials have been conducted with high frequency microwaves (HFM), which allow both faster and more precise localized heating of glass. It will be interesting to see what the future furnace technology will offer.

.jpg)