This paper was first presented at GPD 2023.

Link to the full GPD 2023 conference book: https://www.gpd.fi/GPD2023_proceedings_book/

Authors:

- Milica Baric¹

- Mirela Galic²

- Natasa Stipanelov Vrandecic³

- Geralt Siebert¹

¹Universität der Bundeswehr München, Institut für Konstruktiven Ingenieurbau, Werner-Heisenberg-Weg 39, 85579 Neubiberg, Deutschland

²University of Split, Faculty of Civil Engineering, Architecture and Geodesy, Matice Hrvatske 15, 21 000 Split, Croatia

³University of Split, Faculty of Chemistry and Technology, Rudera Boskovica 35, 21 000 Split, Croatia

Extended abstract

The mechanical behavior of glass is linear until breakage. However, the polymeric interlayers are viscoelastic or viscoplastic materials, which means that their mechanical response has an elastic and a viscous component: the elastic response is proportional to the strain, in contrast to the viscous component which is proportional to the strain rate. The mechanical response of polymeric interlayers is time - and temperature dependent.

Therefore, this research is focused on determining the relationship between the chemical properties of different interlayers and their mechanical resistance. Mechanical properties for sure could be explained by chemical reactions within the production and the process of exploitation; mainly focused on the lamination process of laminated safety glass with Ethylene vinyl acetate (EVA). This indicates an interdisciplinary point of view and explanation.

Ethylene-vinyl acetate (EVA) has been under a humidity experimental program for 4 weeks. The idea was to test the level of water immersion and investigate the influence on mechanical response (Figure 1).

Differential Scanning Calorimetry (DSC) has been conducted for EVA samples before exposure to the humidity experimental program and after it. As a result, the glass transition temperature (Tg) and cross-linking behavior were measured.

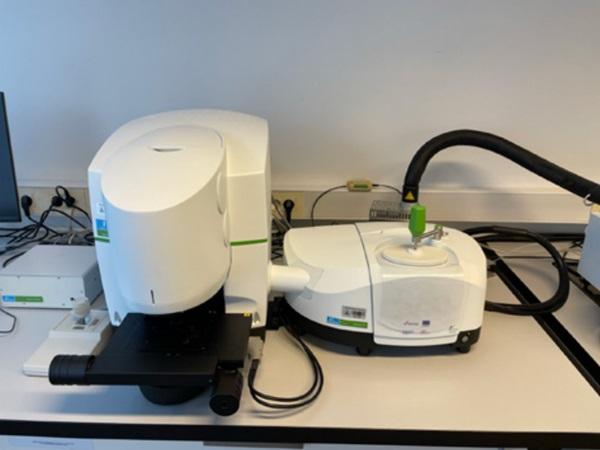

Every 7 days with Infrared Spectroscopy (IR) each sample was examined to detect changes on a chemical level within the material regarding humidity exposure (Figure 2).

Uniaxial tension tests within the regime of finite strains on the interlayer were performed every 7 days. Results were presented in the stress-strain diagram and compared with results that were not under the humidity experimental program. Evaluation of results showed material parameters degradation level regarding exposure to humidity

Understanding the chemistry background was challenging but very valuable not just for understanding EVA polymer but also for understanding how interlayer in laminated safety glass (LSG) and laminated glass (LG) behaves in general.

Parametric analyses presented in this research showed different behavior of the interlayer, construction response, and mechanical resistance in LSG which was exposed to different load conditions and temperature changes.

This paper focuses mainly on EVA interlayer because based on the results so far it has shown promising results in comparison to PVB interlayer which is more common in engineering practice. The research presents advantages and disadvantages for each different load type regarding interlayer chemical response.

References:

[1] Michael A. Kraus. Machine Learning Techniques for the Material Parameter Identification of Laminated Glass in the Intact and Post-Fracture State. 2019.

[2] X. Centelles et al. Tensile test on interlayer materials for laminated glass under diverse ageing conditions and strain rates. Construction and Building Materials 243 (2020).

[3] F. Pelayo, M.J. Lamela-Rey, M. Muniz-Calvente, M. López-Aenlle, A. Álvarez-Vázquez, A.FernándezCanteli. Study of the time-temperature-dependent behaviour of PVB: application to laminated glass elements, Thin-Walled Struct. 119 (2017) 324–331.

[4] W. Stark, M. Jaunich. Investigation of Ethylene/Vinyl Acetate Copolymer (EVA) by thermal analysis DSC and DMA. Polymer Testing 30 (2011) 236–242.