Date: 28 January 2020

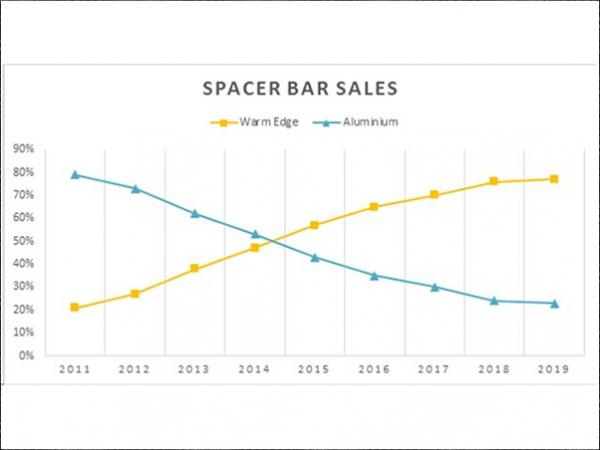

Spacer bars, used primarily to space the panes of glass in double, triple and even quadruple glazing, have seen significant development and a change in market demand over recent years. There has long-been a widespread decline in the demand for Aluminium spacer bars and an increase in the demand for more energy efficient warm edge spacers which has primarily been brought about by changes in legislation dictating improved energy efficiency in windows.

Mark Hickox, Thermoseal Group’s Sales Director shares some of the Group’s insight.

“Going back ten years, the vast majority of the UK spacer market was for Aluminium spacer. Despite the high level of promotion of warm edge spacers as a market differential, there was only a small market for warm edge spacers until revisions to Document L dictated improved U-values and influenced the introduction of the Window Energy Rating (WER) Scheme. Since then, the strive for ‘A’ rated WERs and now ‘A+’, ‘A++’ and in some cases even ‘A+++’ rated windows has influenced the specification of warm edge spacers and any window components which contribute towards increased energy efficiency.

“In 2008, we started developing two of the most energy efficient spacer bars available on the worldwide market – Thermobar warm edge spacer tube and Thermoflex flexible warm edge solution. Since then, our trend in sales has seen a continual decline in Aluminium and increase in the demand for our market-leading warm edge spacer bars.

“We supply to the majority of UK IG sealed unit manufacturers and current warm edge sales account for approximately 77% of our spacer bar sales. We foresee sales of Aluminium continuing to decrease as the demand for warm edge spacer bars grows.

“There is likely to be further increase in the UK demand for warm edge spacers and other more energy efficient insulated glass (IG) components which could be escalated by revisions to document L - the current consultation document suggests solutions which may require the specification of triple glazing in new properties. Should this go ahead, the requirement for triple glazing will mean a significantly higher volume of spacer bar and fittings within each IG unit and so greater demand from manufacturers of premium high-performance warm edge products such as ourselves.

“When you consider the worldwide spacer bar market is in excess of a billion metres of spacer per year, there is enough demand that spacer bar manufacturers will really need to raise their game to meet the volumes required by the market. You may have seen our announcement that we have purchased a new 2-acre production site in Wigan. This new site is currently going through rapid extensive reconstruction to provide further expansion for our warm edge spacer production and development of our Technical Centre and EN1279 test facilities. This is just one of the steps we are taking to move towards our goal to become a world leader in the warm edge spacer market.

“There is also the consideration of the corner keys and fittings for spacer bar. Over the past ten years, our injection moulding division has seen exponential growth and we now produce over 10 million mouldings per year. As the market grows, we aim to continue to produce our own range of bespoke fittings.

“Staying ahead of the market is vital in the current climate, so our prided Technical Centre and EN1279 Test Centre are continually working to develop and improve our warm edge product offering with a view to designing and developing products to help achieve better and better thermal efficiency in windows. Our Account Managers work very closely with our customers in the development of new products, also in helping to keep them informed about new market influences. Triple glazing for example, will have major impact on IG sealed unit manufacturers and therefore the implications in terms of logistics, equipment, time and potential costs should already be up for discussion.”

Thermoseal Group supplies over 2,500 IG Components and a wide range of IG manufacturing machinery. Contact them on 0845 331 3950 or Intl: +44 (0) 121 331 3950. Alternatively, visit www.thermosealgroup.com or e-mail sales@thermosealgroup.com.

600450

600450

Add new comment