Date: 16 April 2019

He has built the company up from a small business with just a single air/tilt table and a single edge polishing machine to one of the leading glass processing companies in Sydney. During the last 18 years, the company has grown step by step, expanding its product range and services.

With this growth, Watson Glass’ demand for equipment has increased too. In 2007 they had a strong investment year, purchasing two new laminated glass cutting tables and their first tempering furnace. In 2016, after the acquisition of a factory in Guildford, also in Sydney, Chris decided to invest again. He increased the number of tempering furnaces to five, covering sites in Sydney, Newcastle and Canberra.

Along with these new furnaces, he was in need of cutting and processing machinery. The new plant would be a combination of replacing ageing equipment and an increase in capacity. In his planning and research stages, Chris attended the China Glass trade fair in Beijing. Whilst in Beijing, he visited a factory which was fully equipped with LiSEC machinery. Said Chris of this visit: “I was so impressed with what I saw there that I invited LiSEC to my office to discuss my current and future needs.”

Shortly thereafter in 2017, LiSEC delivered four cutting tables to Watson Glass: two base CUT for the automatic cutting of float glass, one base LAMICUT with a 3,700 mm bridge for laminated glass and one pre-owned ESL cutting table with edge deletion for jumbo elements. The cutting tables were installed on two sites and are now the basis for an efficient IG production.

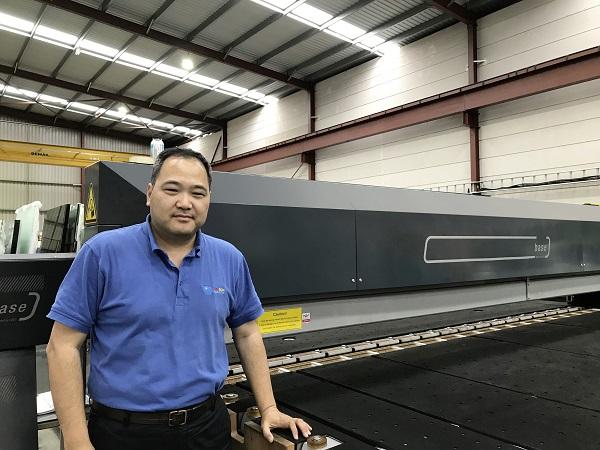

Recently we asked Chris Tao about his experience in working with LiSEC. He said: “Reliability, accuracy and the ease of use have made the LiSEC cutting tables a good fit for Watson Glass. I also appreciate the prompt after-sales-service, if required. I expect further expansion in the coming years and I am looking forward to an ongoing relationship with LiSEC!”

600450

600450

Add new comment