Date: 2 December 2016

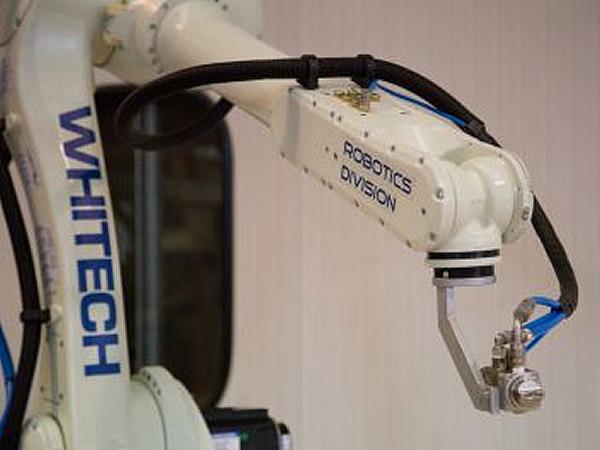

The LEONARDO Programming System for a glazing robot is composed by:

- PTP Industrial Robot RS10L with 10kg payload capacity on the wrist and 1.925mm working range.

- Programming Arm with ergonomic handgrip and VIPER glazing gun.

- Interlocking PC and Software allowing to record the movements executed by the gun installed on the Programming Arm and to convert into a PTP Program for the robot which can be optimized and modified in every single part.

This System combines the convenience of a Continuous Programming (CP) with the flexibility of a Point to Point program (PTP) and with the lightness and agility of a programming arm made in aluminum.

This material makes the arm extremely light and easy to move making the same similar to a normal manual gun.

The programming Arm is installed directly on robot basement only during programming phases. It is then removed by means of fast lockings for all normal working operations of the robot.

This allows also to use the same arm for all the lines installed in the same factory enabling a considerable saving making the system cost effective.

This allows also to use the same arm for all the lines installed in the same factory enabling a considerable saving making the system cost effective.

This system differs from all other glazing robots available in the today’ market where the Continuous Programming, if available, can be executed only by moving the robot arm with obvious problem of heaviness and inertias to move during the manual programming.

Beside that glazing program cannot be optimized or modified.

The LEONARDO software integrates and manage all glazing parameters of the Glaze Dosing System (GDS).

600450

600450

Add new comment