Date: 9 September 2019

“The market in Vietnam for cars is very large with lots of room for growth. People are becoming wealthier, and sitting in a car is more comfortable than being on a scooter, which may be prohibited in the next few years,” says Nguyen Phuong Tran, Production Manager, and son of Long Nhien Automotive Glass’s owners, about his home market. “The Glaston Matrix windshield bending furnace is a stepping stone for us to tap into this rapidly expanding business of hundreds of thousands new cars per year.”

Business for the family did not always have such a positive view to the future. Tran’s father always had a passion for windshields, but that market was highly competitive. He recognized, however, that no one was tempering glass in Vietnam at the time. So, in 2001, he established his company by bringing back some old tempering machinery from Australia that he fixed up.

“He wasted a lot of glass on that line,” Tran laughs. “It wasn’t until 2014 that my parents bought their first laminating line from China when the market started to grow and demand expanded. It was a bending furnace, primarily used for bus windshields.”

YOUTUBE SHOWS THE COOL CHOICE

“I was in the US at the time, where I had lived for eight years. In fact, my plans were to open a restaurant there,” he continues. “But instead, I returned to Vietnam – and that’s where my story begins.”

Tran helped his parents manage the new windshield factory. They purchased a good tempering machine from Italy. Still, they needed a top-of-the-line bending furnace to target the automotive market.

“My whole life, I had no knowledge about glass,” Tran explains. “When I searched on YouTube, Glaston popped up. Others already knew Glaston was the best in the world. After watching the video on YouTube countless times, I felt it was the most beautiful furnace I’d ever seen. It looked so cool! Since we were aiming to move into passenger cars, Glaston Matrix was the only choice. So, I told my parents that if they wanted me to manage the windshield factory successfully, they needed to buy me a Glaston.”

SIGNING THE DEAL

About a year ago, the Vietnamese windshield company contacted Peter Kan, Director of Glaston Singapore, and Glaston’s representative in the region. They had been in touch with each other over the years, but until then, Long Nhien did not have the financing required.

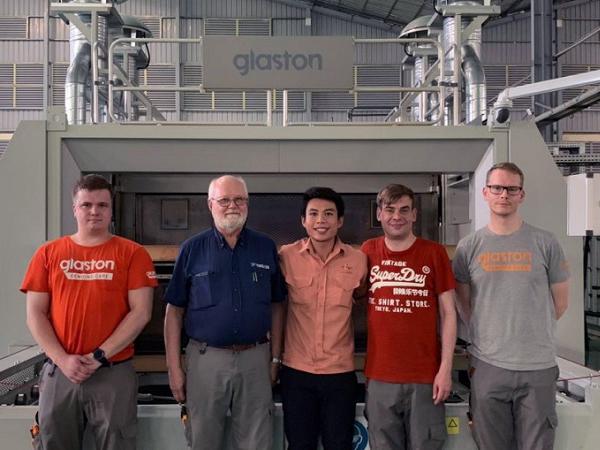

“We told Peter, ‘This time we’re serious!’ He came to our factory and we signed the agreement,” Tran recalls.

QUICK INSTALLATION IS SURPRISE

The new Matrix was installed and commissioned in only 2.5 weeks in midMay. “I had never installed a machine before,” Tran says. “But my parents and everyone in the factory were really impressed. Of the 10 machines we have at our factory, this was by far the quickest one ever.”

Training continued over several days, and the operators felt that it was quite straightforward. It was not as complicated as they had doubted. “It’s easy to catch on and know what’s happening,” was the comment from one operator.

15 TIMES FASTER!

The biggest shock was still to come. Instead of requiring 30 minutes for each windshield bent, Matrix finished in 2 minutes – 15 times faster!

“Yes, the YouTube video showed the windshields coming out of production quickly – but this was much faster than I expected in reality,” Tran admits. He also adds that quality is much better.

APPROACHING THE VIETNAMESE OEM MARKET

Until the Matrix arrived, Long Nhien had been delivering laminated commercial vehicle windshields, primarily within Vietnam. Now, the company aims to target the OEM market.

“Having the best bending furnace in Vietnam will help a lot. Our customers love to hear that their suppliers have European, US or Japanese equipment. They know Glaston to be the top of the line,” he says.

According to Tauno Salonen, Installation Supervisor for Glaston, “Long Nhien now has the capability to produce any kind of normal passenger car or truck windshields with this new Matrix machine.”

Tran agrees: “We now have the capacity to supply all the OEMs in Vietnam. But we’re going to take our time to learn and plan carefully. My vision is to become the first and biggest windshield supplier to serve the growing Vietnamese OEM market.”

With the company’s constant pursuit of excellence, it won’t be long before they achieve that vision from the humble beginnings of the passionate family-run business.

More about Matrix

600450

600450

Add new comment