Date: 22 August 2018

It is a renowned Italian ceramic company to win the first installation of the revolutionary Durst Full Digital Glazing, the completely digital glazing line based on an open system that ensures for the first time a full digital industrial production process.

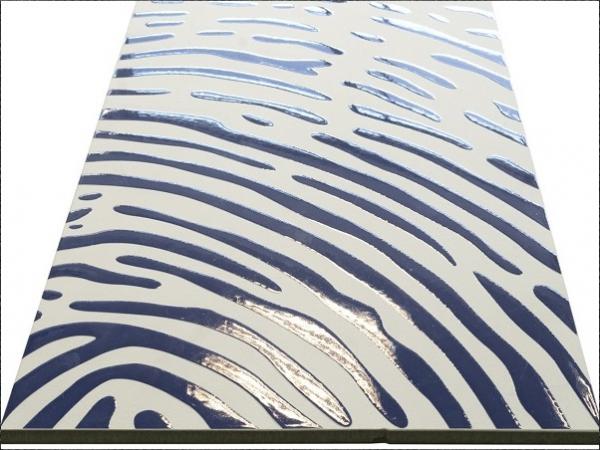

In the large Durst exhibition area at Tecnargilla, in addition to the innovative production system, it showcases numerous industrially produced tiles made by the first customer of the Durst Digital Glaze Single Pass printer.

"Full Digital Glazing is the result of several years of intensive research carried out by our laboratories, also in collaboration with world-renowned external partners chosen to develop dedicated glazes and new designs", - explains Norbert von Aufschnaiter, Director of the Ceramics Printing Division at Durst - "This is the first and up to now only solution for a really true digital tile production; an exclusive technology that the market has been waiting for a long time. The announcement of the first installation gives reality to the dream of many ceramic companies, which in addition is fully responding to the standards of Industry 4.0".

The heart of the Durst glazing line, the Gamma DG Single Pass printer, which uses the patented Durst Rockjet® print head technology, specifically developed by Durst to handle high viscosity water-based ceramic glazes with large particle sizes over 45 microns.

A true revolution that opens up unprecedented scenarios in the development of design that cannot be achieved with traditional glazing systems and alternative digital technologies available to date. Precisely on this topic, the Durst will participate with a speech at the X. Annual ACIMAC Meeting entitled 'Ceramics 4.0: large, digital and sustainable', to be held during the event on September 25.

The Rimini fair will be a truly unique event for Durst: it will also be showcasing two different systems of the Gamma XD Series, recognized as the best ceramic printer in terms of quality, nozzle stability, color consistency, absence of banding, reproduction of details, as well as very low maintenance cost and service needed.

Only some of the performance advantages appreciated by Durst customers who have spontaneously released statements made with the names for the "Durst-Tecnargilla Newspaper" that will be distributed by Durst at Tecnargilla.

Comments that show the great satisfaction for the performance of this digital technology as also stated by Lance Foxcroft, CEO of Ceramic Industries Limited (South Africa): "Reliability, 24/7 productivity, exceptional image quality and low maintenance costs are the main reasons that led us to focus on the Durst Gamma 108 XD systems to successfully achieve our corporate objectives".

The new ultrawide Gamma 208XD printer is the first to show that, thanks to the numerous advanced features that distinguish the Gamma XD Series, adds the ability to decorate large ceramic tile sizes /slabs up to 200 cm wide.

To demonstrate Durst's constant commitment to R & D, another novelty for Tecnargilla visitors: the Durst ColorGATE CMS Durst Edition color management system developed and optimized specifically for the needs and conditions in the ceramic tile production process, able to significantly reduce the number of tests normally required when repeating productions over time due to the normal changes in the process (glaze, firing conditions, etc.).

Thanks to the ability to offer a quick color matching, it is ideal for re-producing the product in smaller lots over time as well as producing the same product in different production locations and/or glazing lines, responding to the current needs for warehouse stock reductions. The Durst system, which already has several installations in the world, can be implemented and operated in all ceramic factories with Durst and Non-Durst digital printers.

The appointment with Durst at Tecnargilla 2018 is in Hall D1 and Stand 155

600450

600450

Add new comment