Date: 9 May 2022

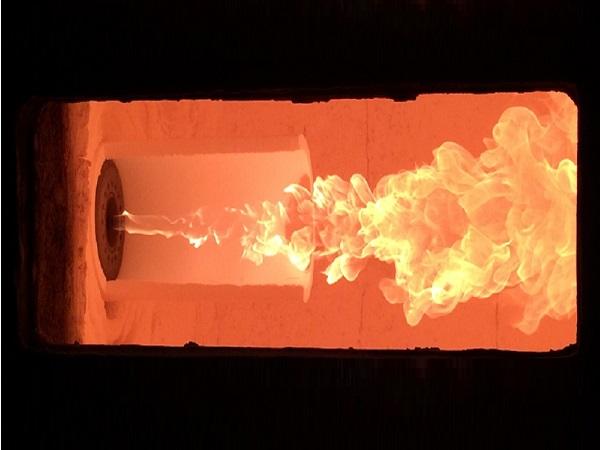

The project objective was to investigate the possibility of using hydrogen in regenerative glass furnaces as a long-term replacement for gas. Both hydrogen-gas mixtures and pure hydrogen were examined.

The HyGlass project was funded by the North Rhine-Westphalian Ministry for Economic Affairs, Innovation, Digitalisation and Energy’s progres.nrw - Innovation subsidy programme and NRW.Energy4Climate. It was also strongly supported by glass manufacturing companies in North Rhine-Westphalia. In addition to the use of hydrogen in the molten glass, the experts at GWI considered logistics and procurement aspects, as well as technical feasibility along the value chain. Another focus was the analysis of hydrogen’s impacts on both combustion and glass quality.

The project results are very positive. “Hydrogen is one of the most promising candidates in the switch-over from conventional to regenerative energy sources,” explained Dr Johann Overath, Director General of the Federal Association of the German Glass Industry. “BV Glas has been assessing the potential of hydrogen for a long time already in the framework of its decarbonisation strategy.” The experiments and simulations have shown that the use of hydrogen has only moderate impacts on combustion as long as the fuel-air ratio and burner output are maintained at a constant level with a control strategy. Both the furnace room temperature and heat transmission remain more or less constant. The use of hydrogen can lead to higher NOx emissions. However, these can be compensated by technical measures at the furnaces.

On the other hand, it is a challenge to minimise the impact of hydrogen on glass quality. “We have established that the use of hydrogen in the molten glass can indirectly cause changes in glass quality such as discolouration. Interestingly, the discolouration is not dependent on the hydrogen content in gas-H2 mixtures, so it cannot be regulated by increasing or decreasing the admixture rate,” explained Dr Anne Giese, Head of the Industrial and Fuel Engineering Department at GWI. However, it would be possible make an adjustment by changing the composition of the glass batch. Further comprehensive research is necessary to achieve the desired long-term glass quality consistency.

To ensure that the glass industry can permanently switch over to hydrogen it will be necessary to increase the availability of green electricity because the project additionally revealed that available power generation capacity (wind and solar) within a 20 km radius of the relevant glass production facilities in North Rhine-Westphalia is not currently sufficient for hydrogen production, even if the full capacity were available to the glass industry.

600450

600450

Add new comment