Thus the knowledge is out there. The aim of the presented project is to collect data on the existing design philosophy and glass failure cases. The investigation includes a survey about how practicing structural engineers deal with different design aspects of glass with a special focus on robustness and serviceability. The current document gives a brief overview about the findings of the interviews.

1 INTRODUCTION

Traditionally structural design codes and guidelines focus on the strength of the material. Since the structural use of glass is relatively new, glass structural standards by necessity may lack rules of such “secondary” issues as serviceability and robustness.

However, structural engineers have to deal with these questions on a daily basis. This suggests that there are good and less good methods, practices or rules to ensure both usable and safe glass structures.

The purpose of the current project was to collect data on existing design philosophy of glass structures and glass failure cases with regard to robustness and serviceability and to provide an overview of these design practices.

2 METHODOLOGY

In the current project 14 interviews with experts were carried out. 7 interviews were conducted in person and 7 via phone. The interviews were anonymous and their duration was approximately 50-60 minutes.

The interviews contained 5 groups of questions, such as:

- General data,

- Questions about experience of the respondent,

- Questions related to robustness,

- Questions related to serviceability,

- Questions on failure cases and problems with existing structures.

The list of questions used at the interviews is not presented here due to lack of space. However, it can be found, with a more detailed analysis and discussion, in an upcoming publication of the authors (Honfi & Overend, in prep.).

The most important selection criterion for the interviewees was to have significant experience of designing or overseeing the design of glass structures (8 to 43 years with an average of 21.7). Most of them work in the UK (8), the rest in Austria (2), Netherlands (2), Germany (1) and USA (1). They have experience either mainly in facade engineering (5) or mainly structural glass (3) or both (6).

The structural engineers we asked about their design philosophy use a variety of design codes, guidelines and other rules (e.g. ASTM E1300, prEN 13474, AS 1288, TRLV, TRAV, DIN 18008 etc.). However, a common opinion was that there is a lack of design aids, thus they have to use everything they could find.

The interviews were analysed to find common patterns in the answers and also different opinions in the structural design philosophy of the answerers. Some of these findings will be presented and discussed in the following sections.

3 ROBUSTNESS

All the interviewees said that robustness is fundamental when designing glass structures, since any glass can break. The question is what will happen when it does. The goal is to achieve safe breakage and avoid collapse. Component failure my never be a threat to human life or endanger the overall stability of the whole structural system.

A detailed description of robustness concepts in structural glass engineering is given by Bos (2009). The answers from the interviews fit very well in Bos’s framework and point out those concepts and methods, which are the most useful for pragmatic structural design.

According to Bos’s work there are different levels to introduce redundancy in glass structures:

- Material level: i.e. with changing the type of glass additional redundancy can be added to the structural element.

- Component level: e.g. adding additional lights and not considering that in the design calculations and provide extra load bearing capacity.

- Structural level: i.e. in case of complete failure of (important) individual elements the system should provide redundancy.

3.1 Robustness at material level

Since glass is a brittle material, most of the interviewees distinguished component and system level only. However some of them mentioned that the type of glass material has direct effect on structural robustness. For example prestressed glass is more susceptible to damaging exposures such as scratching, chipping, nickel sulphide inclusions; while having less sensitivity to others such as general loading, thermal stresses or surface impact (Bos, 2009).

3.2 Robustness at component level

All of the respondents regarded laminated glass as the most fundamental way to ensure redundancy of a glass structural element. The residual load-bearing capacity of the component might be determined by looking at the possible failure scenarios, i.e. breakage of a single, several or all leaves.

If individual layers fail, the remaining intact leaves may still carry the load until replacement of the broken element. To prevent a progressive fracture of the layers, the load-bearing capacity of the damaged element should be enough to resist the loads after the initial failure. Although broken glass can still transfer compressive stresses, the extra layers should not be considered when calculating the load bearing capacity of the structural element.

If all leaves fail, the element can still stay in place due to the load bearing capacity of the interlayer. Since the stiffness of the film is significantly lower than of the glass, thus the deformations will be much bigger. However, this might be useful, since the breakage can be easily discovered until recovery actions are taken place.

The residual strength is also influenced by the fracture pattern of the individual leaves. Glass panes that break into large pieces (annealed glass or heat-strengthened glass) have a better residual load-bearing capacity than glass that breaks into small fragments (tempered glass), since interlocking of the glass shards contribute to the load transfer.

The answers are in line with the recommendations given by Wurm (2007). He also suggests that at least one of the glass layers of a laminated safety glass unit should be made of glass that fractures into large pieces to keep the panel in place after cracking. Since the stresses increase after initial breakage, heat-strengthened glass is normally recommended to use. However it is common to use annealed glass for stair treads, since the cracks give a warning signal for replacement.

It is another interesting question that which loads should be used when checking the residual load bearing capacity of the damaged member.

Lamination is a good robustness strategy; however, it could be a problem for curved panels due to delamination. Fortunately there are other ways, than lamination, to increase the redundancy of glass structural components, such as (Bos, 2009):

- Added film on glass (e.g. inner pane for curtain walls in the UK),

- Additional transparent polymer sheets (i.e. composite structural systems),

- Reinforcement,

- Hybrid elements,

- Protective design measures (discussed later).

3.3 Robustness at system level

According to the answerers to ensure sufficient robustness of the structural system the loss of one or several structural component should be considered and alternative load path should be provided. This means that failure scenario in case of removal of an entire (or several) glass element should be calculated, even in the initial design phase of the design process.

It is important that the designer should consider the stiffness of the structure correctly, which highly depends on the interlayer behaviour and the joints. Note that too much stiffness will attract internal forces and may lead to localized stress concentration.

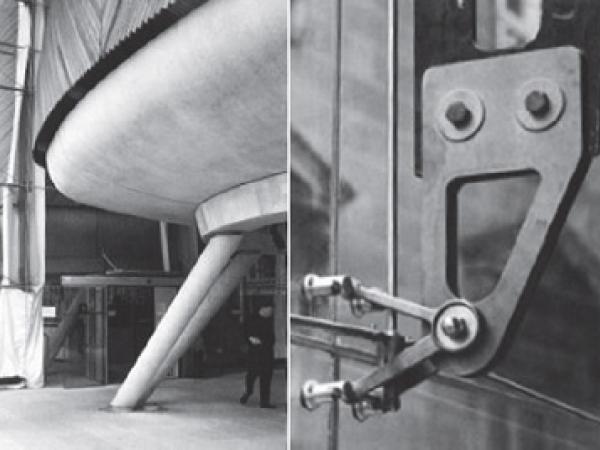

Although in general statically indeterminate structures are considered more redundant than determinate ones, if it comes to glass, better to avoid them. Underestimated stiffness can cause constraints and may lead to problems. A good example of this is the failure of Bordeaux Palais de Justice, where moment stiff connections caused locked in forces and lead to failure of the glass. The fractured fins were replaced by more ductile steel fins (see Figure 1). However, the structure may be considered robust, since the damage did not propagate and caused collapse of the structure (more details in Loughran, 2003).

.jpg)

Figure 1. The covered broken glass (left) and the replacement steel (right) fins at Bordeaux Palais de Justice (Loughran, 2003).

When thinking about the whole structure it is important to avoid local stress concentrations. It should be accepted that glass requires more careful workmanship than other structures. Poor manufacturing and construction principles may lead to stress concentrations.

3.4 Exposures

To see what could possibly go wrong, the designer should identify which are the possible exposures and unforeseen events to consider in the analysis. These exposures and hazards depend on the type of the structure and the considered structural element, thus they should be decided on individual basis. The most important non-natural exposures mentioned at the interviews are;

- Impact,

- Blast,

- Vandalism,

- Damage due to maintenance/installation/manufacturing/material quality,

- Thermal stresses,

- NiS breakage,

- Stress concentrations at fixings.

It should be noted that there are natural and physically generated hazards. The latter ones could be avoided with risk preventing measures, which are extremely important for structural glass design (see later).

3.5 Consequences

The designer should always consider what can occur, i.e. who is using the building, claim the interviewees. The consequences should be differentiated considering the importance of the structure and the importance of the element within the structure.

The consequences of failure are higher if hundreds of people are in the building than if only a couple. Therefore a distinction between private and public building should be made on the first place. Obviously the loads and exposures are also different in private and public buildings. For example a balustrade in a private building needs less protection, since the user might be more careful when approaching it.

Based on the importance and the function of the element, one should allow breakage but not failure. For instance there can be different consequences of failure of the same element at the ground floor and the upper levels.

Typical consequences of failure that should be considered when designing glass structures:

- Serviceability problems or cracking, which require replacement of panels;

- Risk of glass falling, which can cause injuries;

- Risk of someone is falling from height due to the failure of the glass structural element, which can cause fatality;

- Progressive collapse of parts of the structure or the entire assembly.

Almost all the respondents agreed that the more important the element, the more redundancy is needed. As a general rule, one can say for important elements use more extra plies or reinforcement. It is common to treat primary, secondary and tertiary elements differently, see example in Table 1.

Table 1. Possible treatment of primary, secondary and tertiary elements. (Click to enlarge.)

Most respondents use this prescriptive method to ensure extra redundancy for different type of elements. Then the same safety factors is used for all elements; however, more attention should be paid to the key elements. This could mean the following:

- Post failure scenario should be investigated;

- More detailed modelling needed;

- Lower stress level could be accepted;

- High level of protection should be applied;

- Testing is recommended.

The use of partial safety factor method (e.g. prEN 13474) instead of allowable stress method makes it possible to distinguish among consequence classes even on the action side. It means that lower partial safety (and combination) factors may be applied to elements with lower consequences, more details are given by Overend (2012).

3.6 Robustness measures

From the answers of our respondents it is recognized that, there are two main robustness strategies: a.) prevent consequences of failure (e.g. use spare plies in laminates) and b.) prevent failure (e.g. protect the edges).

The former has been discussed in the previous sections, such as:

- Appropriate choice of the glass type;

- Extra lamination;

- Catenary action of the interlayer, to avoid elements from falling down;

- Securing the glass to the framework (structural silicone bonding, chemical);

- Steel reinforcement;

- Glass barriers: continuous handrails provide extra redundancy.

The latter group means to diminish the risk that the glass will be broken. The following design measures were suggested by the respondents:

- Protecting the edges (with metal profiles) to avoid cracking, especially in public areas;

- Protection against impact (e.g. devices to stop trolleys to hit balustrades);

- Recessing the middle layers to make it less likely hitting them;

- Measuring the actual prestress level of the glass surfaces, although it is a new and not very common method;

- Testing (soft body impact, hard body impact);

- Client should understand the risks;

- Avoid glass fins at the ground floor level, interrupt them to eliminate the risk of crashing into them;

- Make the glass panels easily installable, no labour on site;

- Quality control at the design, manufacturing and the execution phase;

- Operational manuals (e.g. temporary supports must be placed if one ply breaks);

- One should think about how to replace the broken glass, not to cause additional danger.

3.7 Detailing

Detailing is a key to the success, since poor detailing may cause problems. The performance even depends on e.g. who and how drilled the actual hole. There are always new products, new technical solutions on the market, which may perform better than previous ones. For example injectable adhesive mortar seems to work better than the previously used epoxy. It is easier to use and helps to prevent stress concentrations. On the other side it cannot be used at higher temperatures. In contrast, structural silicone is problematic to use effectively in cold weather conditions.

A recently built all glass roof shows a good example of ensuring redundancy both on component and system level. The girders consist of laminated fins with three plies. When two plies fail the girder still can carry the load (robustness on component level). When the girder fails completely there is second load path via the secondary beams to the parallel beams (robustness on system level).

A similar example can be found in Figure 2 taken from Bos (2009), where a steel bridge over the main beam serves as a back-up for the adhesive bond between the aluminium joint component and the glass.

.jpg)

Figure 2. Back-up steel bridge over the main beam (Bos, 2009).

4 SERVICEABILITY

Concerning serviceability the answers we got were not as consistent as in case of robustness. There were many comments on the lack of proper design guidance in codes. On the other side everyone stressed that serviceability criteria are very project specific.

4.1 Deflections

The common opinion was that the deflection of glass itself is not really a problem. It is flexible and can bend quite much. However, human perception to glass is probably different than towards traditional structural materials, since it is considered to be fragile and dangerous. Transparent structures catch more attention from users than ordinary structures, thus deflections should be handled strictly.

The main problem with deflection is at the connections. If the deflections of the panels are too excessive and the joints cannot deform sufficiently, the bond can break.

With regard to vertical glass planes generally 2 serviceability criteria should be ensured: appearance and comfort (i.e. feeling safe). To the former, the appearance criterion, there are no straightforward limits. It should be decided based on engineering judgment and consultation with the architect or the client. The later, the comfort criterion is associated with vibrations. The limit should ensure that movements of the panels are not annoying to the occupants. Movements and deflections of large panels are often scary. It also plays a role if the panel is inside or outside, i.e. loaded by the wind or just a partition wall occasionally hit by people. Various limit values were mentioned by the interviewees from L/1000 to L/30 (or even no limits) depending on the function of the element, the structural system etc.

In case of floors the respondents also mentioned different values from L/200 to L/500; however usually they said that the vibrations should be checked.

Deflection of beams is not really an issue, since the deflections are usually small even at ultimate limit state (ULS). Furthermore there is no finishes on the top of them. More important problem is to avoid instability (e.g. lateral torsional buckling).

Deflection of glass supporting elements could be more interesting than the deflection of the glass element itself. Sometimes during the design process the supporting elements are already there or designed by a partner. The required information always should be obtained and try to balance the displacements and movements of the structure.

Half (7 of 14) of the interviewees said that deflection limits often govern the design. Beams, fins, cantilevers and columns (i.e. primary and secondary structural elements) are usually stress controlled and deflection limits are of less importance. Floors and stair treads are more deflection limit governed; however, it is probably due to avoiding vibrations and the appropriate limits are not always clear.

Deflections tend to govern the design where local stress concentrations do not cause problems (i.e. no holes in the panel). Insulated glass unites (IGU) and panels made of toughened glass are more sensitive to the deflection criterion.

4.2 Vibrations

6 respondents said that the vibrations should always be controlled by limiting the natural frequency of the structural elements. Since the panels are usually regular with simple support condition, the task is not that complicated. However, 2 of the answerers said that vibrations should not be checked or controlled at all, since the deflection limits ensure that they will not cause any problem.

Those who said that the natural frequency should be checked said that in general it should be above around 4 Hz. For stairs different criteria may be set for different vibrations:

- Vertical frequency of the treads should be above 4 Hz;

- Horizontal frequency should be above 2 Hz for circular stairs;

- Horizontal frequency should be above 3-4 Hz for straight stairs.

The opinions about the importance of vibrations are quite different. 3 persons think that they are often important, 4 said sometimes and 7 claimed that they are rarely important. They considered them important mostly for staircases, floors and pedestrian bridges and sometimes for external facade elements. However, vibrations for facades seem to be very rarely important, only if there is no proper wind load.

5 EXISTING STRUCTURES

5.1 Full collapse

Only 2 respondents said that they have encountered full collapse of glass structures. One of them mentioned two cases.

The first one was a bolted assembly with glass cantilever fins of a shopping mall, where all 3 fins broke during opening hours and a few people got hurt. The reason was high wind on the façade and poor detailing. The second case was similar with ground based cantilever glass fins, embedded (150-180 mm) in a box, bonded with epoxy. The reason of the collapse was poor installation principles. They put the fin into the box and tried to pour the epoxy after down the side. It did not go down to the bottom, thus the fins were not fully embedded. It happened at night, nobody got injured. However, the facade fell apart.

The other one mentioned the case of the glass roof of a swimming pool in Moscow, which collapsed under the weight of snow in 2004. The collapse sent glass shards, metal girders and ice falling on the swimmers and caused panic. At least 26 people died and more than 100 were injured (The Telegraph, 2004).

5.2 Partial collapse

Partial collapse is somewhat more common, 5 engineers said that they have experienced it to happen. Breakage of individual planes is not common, but sometimes they break and fall out. Examples are mostly staircases and the reason is usually poor design and/or construction. Usually secondary elements of staircases break, sometimes even under dead load.

5.3 Breakage

Breakage of glass elements is very common, 12 of the 14 persons interviewed mentioned some examples. Someone said that breakage occurs all the time (2-3 times a week) especially at toughened glass. The main reasons are thermal stresses; initial cracks; chipping and smashing at construction and maintenance or due to vandalism; or simply not considering a particular loading. Here is a list about some particular cases that has been mentioned:

- Initial failure at construction phase due to cracks. Reason: poor glass quality.

- Failure of the outer ply of a window due to shooting.

- Breakage of a roof panel due to thermal cracks. Only one ply failed.Reason: poor edge polishing led to stress concentration and cracking.

- Glass panel broke 1 year after completion. Reason: poor quality of temper. There was no danger.

- Spontaneous failure of a vertical glazing due to impurities in NiS crystals.

- Tightening up of bolted connections during construction causes local stress concentrations and 1 layer failed.

- Top sheet of glass floor failed due to impact.

- Glass floor in a crowded public place, only the first light damaged.

- Breakage of glass panels, since the protection was put on the wrong side.

- Breakage since the tempered glass was deigned, but annealed was installed.

5.4 Serviceability problems

The majority of the answerers (10 of 14) claimed that they have seen serviceability problems in existing glass structures. Especially if the client does not follow the operational manuals, problems can arise due to deterioration.

Some examples are as follows:

- Bolted cantilever fins not fixed properly. Excessive deflection of the whole assembly.

- Cantilever fins were attached properly but the supporting structure was inadequate (timber framework).

- Excessive movement at large glass sheets (3m x 5.5m). Too thin windows are sometimes very flexible. Example: The Black Diamond (The Royal Library in Copenhagen, see Figure 3) movements of the windows are almost scary.

- 2 edge supported glass walls are sometimes so flexible, that they vibrate even if people are touching them.

- Vibration problems at a staircase with long treads. The vibration criterion was improved after that case.

.jpg)

Figure 3. Façade of the The Royal Library in Copenhagen.

6 CONCLUSIONS

The survey clearly showed that there is a need for more comprehensive design aids and recommendation for structural glass engineering. However robustness and serviceability requirements are not always easy to quantify in terms or numbers and formulas. Advanced engineers prefer to use some kind of performance criteria, rather than prescriptive rules. On the other side less experienced designers might be afraid of too general guidelines. As a compromise general performance criteria might be given in the codes and good practices and design examples for simply cases might be provided.

Robustness is essential when designing glass structures, since glass is a brittle material. One cannot completely avoid glass to break, but it is possible to lower the risk. The engineer should design the structure in such a way that it should fail safely. Glass designers should always think in failure scenarios and constantly ask the question: what can possibly go wrong? The strategies to provide redundancy of the system include measures to reduce: a.) the probability of damage due to different exposures and b.) the probability of failure of individual elements due to damages and the consequences of failure.

Serviceability issues are probably less important than safety and robustness; however, they might be more and more significant as glass structural system become more and more structurally optimised. Such a tendency can be seen looking at the development of traditional structural materials. When engineers get more courage and start designing more slender structures, stability and serviceability questions become even more important. Thus improving serviceability criteria is also essential. Furthermore the public’s perception to glass structures is different than to other structural materials due to its brittle nature and the dangerous shards from fracture.

The reasons of structural failures in existing structures should always be discovered, analysed, discussed and disseminated, since one could learn much more about them than from any laboratory tests and computer models. Remember, real life can never be perfectly simulated!

Finally we should claim that glass is a transparent material and it should be designed and build in a transparent way. That means that, the possible errors and exposures, the construction methods, the load path through the structure and the consequences of failure should always be clear and well understood to provide a safe and well serviceable structure.

AUTHORS:

D. Honfi

Department of Structural Engineering, Lund University, Sweden

M. Overend

Glass and Façade Technology Research Group, University of Cambridge, UK

REFERENCES

Bos F.P. 2009. Safety Concepts in Structural Glass Engineering – Towards an Integrated approach. PhD Thesis, TU Delft.

Honfi, D. & Overend, 2013. M. Structural glass – Learning from failures. (in. prep.)

Loughran, P. 2003. Falling Glass: Problems and Solutions in Contemporary Architecture. Basel – Boston – Berlin: Birkhäuser – Publishers for Architecture.

Overend, M. 2012. Glass. In John Bull (ed.), ICE Manual of Structural Design: Buildings: 397–416. ICE Publishing: London.

Wurm, J. 2007. Glass Structures: Design and Construction of Self-Supporting Skins. Basel – Boston – Berlin: Birkhäuser Verlag AG.

The Telegraph. 2004. Moscow pool roof collapse kills 26. Available at:

http://www.telegraph.co.uk/news/1454404/Moscow-pool-roof-collapse-kills-26.html.

Source:

COST Action TU0905 Mid-term Conference on Structural Glass

Edited by Jan Belis , Christian Louter and Danijel Mocibob

CRC Press 2013

Pages 527–535

Print ISBN: 978-1-138-00044-5

eBook ISBN: 978-0-203-79741-9

DOI: 10.1201/b14563-72

The doi link to the paper can be found here:

http://dx.doi.org/10.1201/b14563-72

An online version is here:

http://www.crcnetbase.com/doi/abs/10.1201/b14563-72

The webpage record of the book here:

http://www.crcpress.com/product/isbn/9781138000445

.jpg)