Date: 28 April 2023

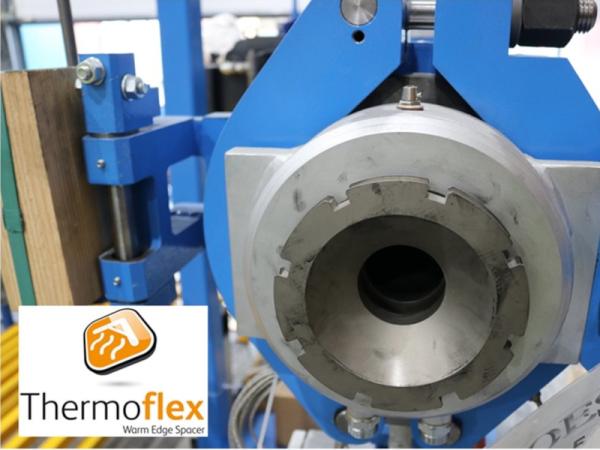

The new twin-strand extruder will sit alongside two existing models, and can produce all thicknesses of Thermoflex, including 4.8mm, 6.3mm and 7.3mm, and air spaces up to 28mm, in twin strand. And because it is quicker than the company’s existing equipment, it can produce more than double the quantity of product per shift on certain product types.

“When we first started extruding Thermoflex, we decided we should be in control of the whole process,” Thermoseal Group’s Sales Director Mark Hickox explained. “So, we compound the rubber, extrude it, vulcanize it, bake it, laminate it, and then box it ready to go to the customer. No other manufacturer in the UK has the same level of control over each step of the manufacturing process.

“And because we regularly test all our products on site, we can guarantee their quality when they are delivered to our customers.

“Our continued success has meant that we’ve had to continually upgrade our manufacturing facilities. Rather than increase our manufacturing footprint – which would significantly increase our energy consumption – we've invested in a new extruder which can double our capacity without moving to a bigger site.”

While the new extruder increases the capacity for standard 20mm Thermoflex – the most popular spacer bar in UK double glazed units – the investment also prepares the component manufacturer for increased demand in other sizes.

“Widespread triple glazing specification is on the horizon, thanks to the lower U-values expected of windows following the implementation of the Future Homes Standard in 2025,” Mark said. “This will require more units with different thicknesses of glass and spacer bar.

“There are still two years before the new Future Homes Standard comes into force, but we need to be prepared for the changes now,” Mark says. “Some of our customers are already making the necessary changes to their operations, because ordering new equipment and adapting existing procedures takes time, and it’s not the sort of thing you want to leave until the last minute.

“Those companies that prepare now will be the ones ready to take on the extra work when the new legislation comes into force. Our team of experienced Area Sales Managers are happy to help you on that journey, and can advise you on equipment, production methods, and automated or manual production options – you’ll find that we are not biased to any specific type of insulated glass production because we manufacture or supply all types!”

The new extruder will also support Thermoseal Group’s growing export market, which is expected to grow dramatically as more countries adopt stricter standards for energy efficient building materials.

“The global market for flexible warm edge spacer bar is currently about 600 million metres,” Mark said. “We have no problem investing it because we know the market is going to be billions of metres in the future.

“We might be the market leader in the UK for spacer bars, but globally nothing's happened yet. The market is truly going to be huge, and we intend to be at the forefront of technology.

“We want to continually develop higher performing products, reduce their cost, and then reduce the energy cost to produce those products, which in turn will help people invest in energy saving products for their home.”

For more information, please visit www.thermosealgroup.com, or call 0121 331 3955.

600450

600450

Add new comment