Date: 10 February 2025

As one of the world's strongest solution partners for pharmaceuticals, biotech, healthcare and cosmetics industries, Gerresheimer develops and manufactures primary packaging for medicines and cosmetics.

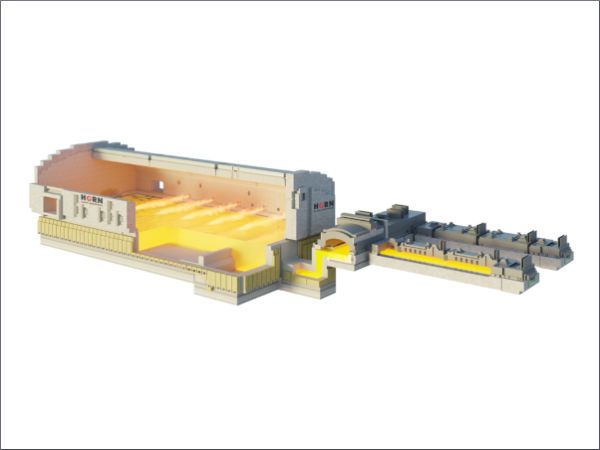

Gerresheimer contracted the glass melting technology specialist HORN to replace the existing furnace and to convert it to the latest low-CO2 glass melting technology. The well proven oxyfuel technology is used together with the in-house E-Fusion Powerboosting as a hybrid technology. The new hybrid oxyfuel furnace for the plant in Lohr am Main will produce container glass much more sustainably in the future.

Under the construction supervision of HORN, the new melting furnace will initially be built with four forehearths from the HORN GCS301-advanced series in the first quarter of 2025. The furnace is designed for a maximum daily output of 390 tons per day with a total of five production lines at the end.

Gerresheimer assigned HORN to deliver a complete package of design, engineering, delivery of the steel structure and equipment as well as the complete construction works. The equipment includes the complete natural gas heating for the furnace and forehearths as well as their measuring and control equipment together with a SCADA process control system. Proven loading technology as cooling water supply and E-Fusion power boosting are also used. The use of up to 60% of electricity will ensure a significant reduction in CO2 emissions during glass melting.

The complete construction works and heating-up are accompanied by the HORN supervisor team to ensure that the system is commissioned without any problems. In addition, Gerresheimer's operating personnel will be prepared to take over the system through specially tailored training.

600450

600450

Add new comment