Date: 15 September 2016

An all-new flat tempering line is presented as well as Glaston Insight, a platform that brings new smart tools to improve machinery productivity, uptime and profitability.

The performance of the new tempering lines is showcased twice per day when Glaston tempers glass live.

Glaston Insight – improved machinery productivity, uptime and profitability

Today’s smart technologies allow machinery to be interconnected with each other and with its operators, regardless of their location.

With smart data analysis huge amounts of data can be combined into valuable information giving increased efficiency, lower costs in business processes as well as faster response times.

Glaston Insight is the platform that gathers global processing data and transforms it into business excellence. Glaston Insight brings new smart tools to improve machinery productivity, uptime and profitability.

The heat treatment machinery can be monitored online and feedback on production, quality and maintenance is immediate.

An online connection provides a range of new benefits. Remote access to machinery-related data gives the possibility to analyze faults without actually being at the factory.

In addition, online access gives accurate and immediate feedback on the end products processed as well as on the machinery throughput.

Online machinery also delivers feedback on targeted levels, and can provide tips and tools to automatically improve efficiency.

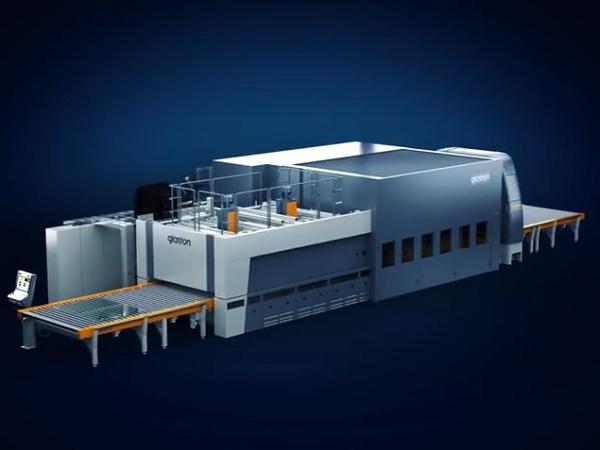

New flat tempering range

At Glasstec in 2010, Glaston launched the RC200™ and FC500™ flat glass tempering furnaces. Since then, over 300 lines have been sold, making these furnaces the most successful premium tempering lines in history.

In 2016, Glaston is again setting new flat tempering standards with the renewed RC and FC Series. The RC series offers extremely high flexibility, ease of use and consistently high glass quality.

FC Series – the Masterpiece of Intelligence

The FC500™ furnace was developed specifically to meet growing market demands for lower energy consumption, higher glass quality and increased capability to temper a larger number of coated glasses, such as Low-E.

The renewed FC series provides a range of cutting-edge technological features for even more efficient flat glass processing making it the most intelligent tempering solution in the market.

In addition, Glaston offers the new FC and RC Series based heating chamber replacements as upgrades to all existing tempering lines. This is a cost effective and fast alternative to upgrade an existing glass tempering line with today’s technology.

At Glasstec, Glaston also introduces its innovation to the ProL flat laminating line that allows lamination production to be managed using only the glass thickness, leaving all other parameters unchanged. This innovative unit is also available as an upgrade to all laminating line brands and will increase line yield, reduce waste and improve the glass quality.

Live tempering

To make the most of smart connectivity Glaston’s experts are tempering glass live at Glasstec. The performance of today’s premium tempering lines can be experienced twice per day at Glaston’s stand in Hall 15, Booth A 41. /p>

Glaston Insight - Excellence comes standard

https://www.youtube.com/watch?v=j7rQCnQ3s0k

What can online access to my machinery data (IoT) do for me?

http://glastory.net/iot-online-access-to-machinery-data/

The rise in laminated glass – Adding safety and durability to modern design

http://glastory.net/the-rise-in-laminated-glass-adding-safety-and-durability-to-modern-design/

600450

600450

Add new comment