Date: 21 February 2022

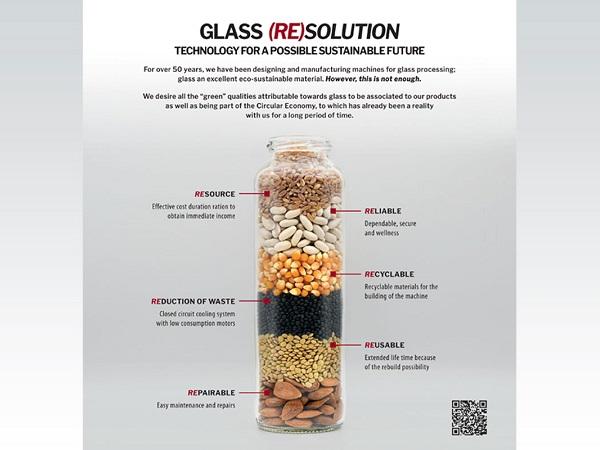

All the qualities, typically associated with our "green" material, must in our opinion, also be associated with our company and our way of working.

How is it possible? Our guide on the path to sustainability is bounded by at least six milestones, which inspire our modus operandi and explain the results.

RESOURCE

Our machines, like glass, must first of all be "resources" in order to generate immediate income. This is achieved not only thanks to their high productivity, but also to the convenient cost-duration ratio.

RELIABLE

For us, reliability turns into social sustainability: taking care of the safety and health of our employees and our customers is always important for us.

RECYCLABLE

The materials we choose to use to produce our machines are recyclable, with a very low environmental impact.

REDUCTION OF WASTE

Sustainable behavior takes care not only of reducing consumption but also of eliminating inefficiencies. Closed circuit cooling and low consumption motors are our answers.

REUSABLE

The circular economy taught us to consider the life of some machinery as cyclical. Thanks to revamping our machines often come back to life, renewing themselves and extending the duration of their life and their productivity.

REPAIRABLE

The correct maintenance and repair of the machines extends their life and protects them from some technical problems. Our assistance service, even remote, therefore also contributes to improving productivity.

By following these guidelines it is possible to design and build glass processing machines in a sustainable way, thus contributing to a now imperative green economy.

We are still working in this direction since long ago, and you?

600450

600450

Add new comment