Date: 18 October 2024

In an era where automated processes are gaining more and more importance, thus reducing manual human intervention, quality assurance systems must also work reliably and independently. As a pioneer of this movement, Semcoglas has been relying on innovative solutions, including glass quality inspection, for years.

Initial Situation

- Incorrect evaluation of panes with defects within tolerance

- No automation possible with previous scan results

- Lack of interface and communication with the insulating glass lines

- Automatic adjustment of customer-specific quality requirements

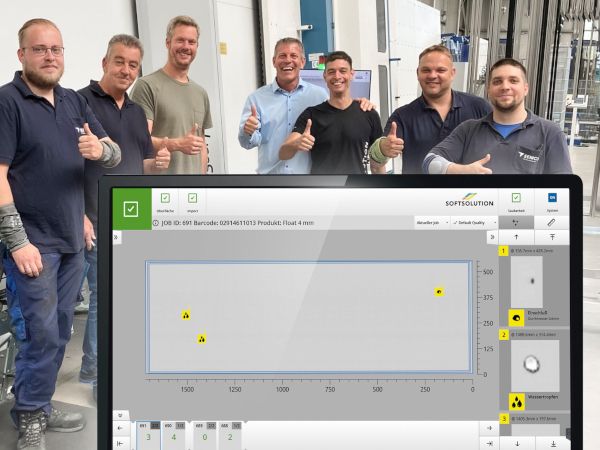

As a leader in glass quality inspection, Softsolution partners with SEMCO in this dynamic process, providing cutting-edge technologies. Mr. Markus Stefan from Softsolution interviewed the project manager, Mr. Michael Wienker, about the recently installed LineScanner at the SEMCO company site in Kropp.

Q: How has Softsolution’s LineScanner at SEMCO Glass in Kropp improved automation and quality control?

A: Michael Wienker: The LineScanner, standing 2500 mm tall, was installed on the ISO line at SEMCO Glass in Kropp as part of an internal project to enhance glass quality inspection. This highly automated production line, operated by two staff per shift, includes a fan cart system (infeed), a frame setting station, two cork applicators, and an unloading robot. However, automation relies not just on hardware; effective software and communication between components are essential.

Softsolution introduced a third quality status, “potentially good”, in addition to the existing “good” and “bad” statuses. This new status helps address “stubborn contamination” issues. The LineScanner communicates one of these three results to the production line.

An interface between the ERP system and LineScanner allows for customer-specific quality requirements to be applied to each insulating glass unit. Glasses without defects proceed to the frame setting station, while defective glasses are automatically ejected. For potentially good glasses, the line stops for manual inspection.

Integrating the ERP system, quality scanner, and insulating glass line has streamlined staffing and boosted productivity. This enables SEMCO to manage rising costs while remaining an economically and qualitatively attractive option for customers.

Q: What features distinguish the LineScanner system and Softsolution?

A: Michael Wienker: We chose Softsolution’s LineScanner for this project because of their open approach to new requirements. They focused on “HOW” to implement automation with the scanner system, not “IF” it was possible. Softsolution actively supported and advanced our idea of an operator-free inspection station, which ultimately led to the project’s success.

The LineScanner exceeded SEMCO’s expectations, offering advanced error detection with multiple classification options. Integrating with our ERP system, it eliminates the need for manual selection, automatically applying criteria to each new unit. One of its standout features is the ability to distinguish water droplets and glass bubbles with precision. Notably, the system can detect patterns of small water droplets which, while not grounds for rejection, serve as early warning signs for potential washer misalignments, allowing for proactive maintenance.

The LineScanner’s standout feature is its intuitive slider function, which allows us to fine-tune rejection criteria based on defect size and contrast. This precision is further enhanced by specialized glass encoders that measure the exact speed of each pane, ensuring accurate defect assessment. For instance, when evaluating inclusions, the system measures only the actual defect, ignoring the surrounding “white halo” that often leads to false rejections. This level of accuracy means we can adhere to strict quality standards without unnecessarily discarding acceptable panes, striking an optimal balance between quality control and production efficiency.

Q: Where do you see the advantages of the LineScanner in your daily work and when handling customer complaints?

A: Michael Wienker: The LineScanner’s archive documents all scan results, which can be retrieved at any time using customer name, order number, serial number, barcode number, and other criteria. The search and filter functions are intuitive and self-explanatory.

It was important for SEMCO that defects that don’t lead to rejection but are present can be displayed and discussed with the customer. This option can be selected or deselected in Softsolution. Quality can be objectively assured with the help of a certificate printout for each glass pane.

We can evaluate single or multiple defect types (e.g., scratches, inclusions, contaminations) over desired periods, using the search dialog in the main archive display. This enables quick and easy analysis of main production defects, facilitating their resolution. To better evaluate suppliers, we can also filter by glass types (e.g., tempered glass) in the search dialog.

With the LineScanner Management Console, we can access scan data anytime and anywhere via mobile phone, tablet, or PC, effectively monitoring production. In this console, we set custom parameters on our mobile phones. If these are exceeded or not met, we immediately receive an email notification – for example, if piece counts fall below a minimum value or rejection rates exceed a maximum value.

About Semcoglas Kropp:

This success story demonstrates SEMCO’s commitment to quality, innovation, and continuous improvement of its insulating glass manufacturing processes.

SEMCO Kropp was built from the ground up in 2009 and has since been steadily transformed into one of the most automated facilities in the SEMCO Group.

About the SEMCO Group:

Founded in 1977, SEMCO has become a leader in the European flat glass industry. With a workforce of over 1,800 employees across 23 locations in Germany and Denmark, SEMCO serves as a reliable partner for glass solutions in interior design, as well as for windows and facades. The journey from 1977 to the present is a story of progress and innovation.

600450

600450

Add new comment