Date: 12 December 2023

In 2021, Tianjin NorthGlass Industrial Technology Co., Ltd. integrated a horizontal LineScanner immediately after the tempering furnace for the first time to conduct anisotropy and edge stress inspections.

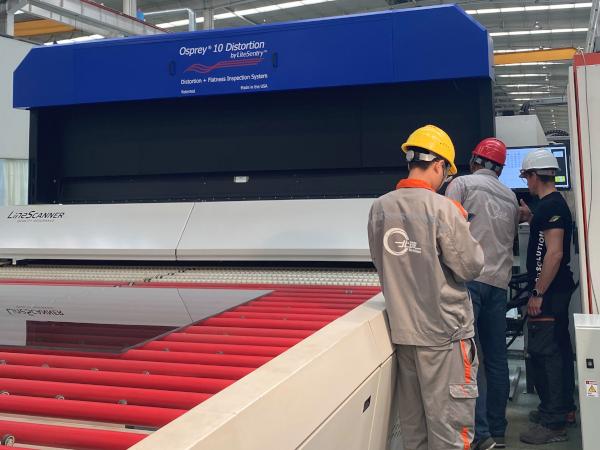

Following the successful deployment of the initial LineScanner, NorthGlass implemented a second LineScanner and an Osprey 10 Complete after the tempering furnace. This made it possible to not only examine anisotropy but also assess the distortion of tempered glass.

As a subsidiary of Luoyang NorthGlass Technology Co., Ltd., the company has made significant investments to establish a major glass deep-processing enterprise equipped with state-of-the-art technology from NorthGlass.

The company boasts impressive production capacities, including an 18-meter ultra-large LOW-E production line covering 8 million square meters and additional production lines for tempered, laminated, and safety insulated glass. Tianjin NorthGlass’ flagship products, ultra-large energy-saving glass, and structural glass products are utilized in Apple’s “Glass Spaceship” project in the United States.

Using the LineScanner ensures precise monitoring of anisotropy in tempered glass, allowing timely adjustments in the tempering process. These real-time data provide comprehensive documentation of glass quality, helping to avoid uncontrolled operations and ensuring consistent quality in the tempering process. The LineScanner examines anisotropies, generates thermal images, and determines the edge stress of each produced pane, highlighting its uniqueness.

The Quality Manager at Tianjin NorthGlass explains: “The LineScanner can accurately monitor the anisotropy of tempered glass and provide timely instructions for adjusting the tempering process. This ensures the stability and traceability of quality control.”

600450

600450

Add new comment