Date: 19 February 2025

This strategic move enhances LiSEC’s technological capabilities and market presence. cericom GmbH, known for its pioneering laser technology and precision in glass processing, has already been a valuable part of the LiSEC Group. Transforming it into LiSEC laser processing allows LiSEC to combine its strengths to offer superior solutions in the glass processing industry.

Looking to frost, structure, or drill glass? Look no further than LiSEC laser processing for the perfect solution!

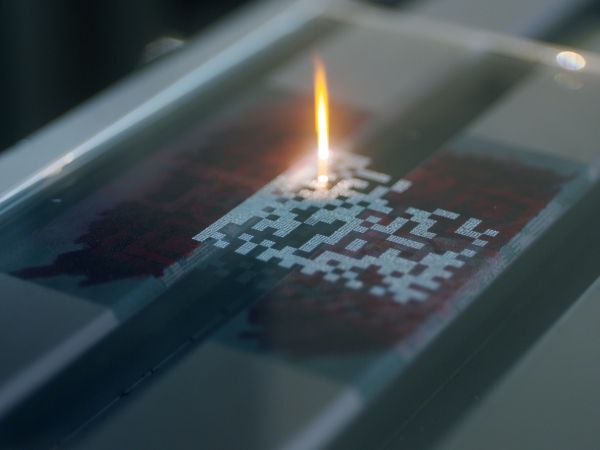

LiSEC is well known for its broad product portfolio as all.in.one:solutions provider. Adding laser systems extends this product portfolio even further and provides new possibilities to our customers. As the demand for glass processing continues to rise, LiSEC laser processing offers a comprehensive range of solutions tailored to meet the unique needs of various branches in the glass industry. Whether you want to frost the surface of the glass, remove or structure coatings, drill in complex shapes contact-free, or even save the life of birds: With LiSEC's glass laser processing solutions, sophisticated projects in architecture and design can be realized. The LiSEC laser processing machines are equipped with the latest laser technology and allow you to decorate and drill glass easily and precisely.

Laser processing – the ideal solution for producing bird friendly glass

Bird-friendly glass is designed to make glass visible as an obstacle to birds, thereby preventing bird deaths. In the past, black bird-shaped stickers were applied to glass surfaces as a deterrent, but these proved ineffective. Today, adhesive films with patterns such as stripes or dots, fly screens, special window paint, or cord curtains are recommended.

However, these solutions are often unattractive, they are impractical for most large buildings, and they also obstruct the view. An alternative is bird-friendly glass, which is produced using laser processing machines. The laser modifies the glass so that its transparency and reflectivity are altered. This allows birds to see the surface immediately and avoid flying into it. What may seem like a minor difference to humans can be a matter of life and death for birds. By reducing the rate of bird strikes, LiSEC can minimize human intervention in the ecosystem. This approach not only protects bird populations but also maintains the aesthetic and functional integrity of buildings.

Laser processing offers a practical and visually appealing solution to the problem of bird collisions with glass. It ensures that buildings remain both bird-friendly and visually unobstructed, contributing to a more harmonious coexistence between human structures and wildlife.

Find out more about LiSEC laser processing

With LiSEC's commitment to global delivery, businesses around the world can benefit from these specialized laser processing machines all around the globe.

Visit LiSEC‘s website at https://www.lisec.com/solutions/individual-machines#collapse-36 to learn more about the laser processing machines.

600450

600450

Add new comment