Date: 14 December 2016

In order to fulfill the current regulations regarding NOx values and also to save more energy when producing glass HORN Glass Industries AG developed batch charger HVR700F-2P.

HVR700F-2P is very reliable and HORN Glass is very satisfied with its performance, however, HORN never stopped learning and always looks to improve its products.

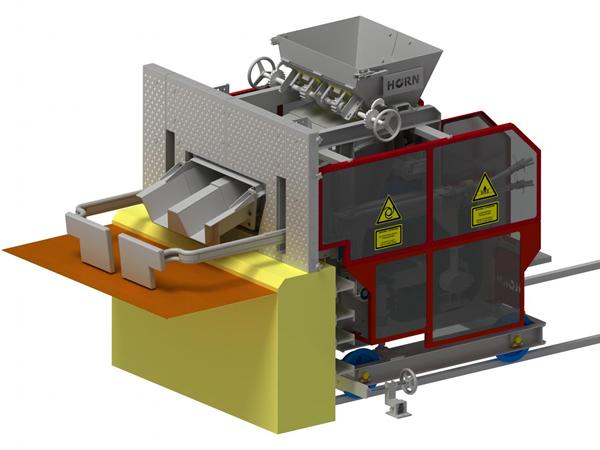

To meet HORNS customers’ requirements HORN invented its latest batch charger HVR600S-2P and HVR700S-2P.

The difference is the “S” in HVR600S-2P. It stands for servo drive where as “F” in the previous model HVR700F-2P stands for frequent drive.

In order to positively influence the batch charging process by defined paddle controls the gear motors were replaced by servo drives and can be set into three different operating modes, which are: Independent, Synchronal and Batch cutting.

Here are the biggest advantages of HORN’s latest models:

- Orientated on HVR700F-2P we improved the profile of the protective shield into an even shape which makes it completely dust proof as it perfectly fits to the doghouse cover.

- HVR600S-2P as well as HVR700S-2P work with two water cooled servo engines. The servo engine is able to rotate from 0° till 359° degrees and is separated into 0..359.000 increments. For one rotation 18 segments can be defined individually. Important is that each segment can define the position and speed of the paddle which moves within the segment.

- The frame is adjustable in its height

- The output of the HVR600 can be up to 240tpd and 420 tpd of the HVR700

- Optimal distribution of the batch through separated paddle control. Thus a better melting of the batch can be achieved.

- HVR600S-2P and HVR700S-2P are easy to maintain due to the fast changeover of the paddles, it includes an inspection chamber, is moveable and easy to repair within 10 minutes without temperature loss through the doghouse.

- A peephole included within the doghouse cover enables easy inspection of the charging process

- Reduction of emissions in terms of NOx and dust

- Suitable for preheated batch

The new charger model is designed to positively influence the batch charging process by defined paddle control.

Through the servo drives, which are centrally controlled by a 2-axis control, it is now possible to define the absolute number of vertices and be able to define the transition rate percentage of the set point while oscillating. The individual vertices can easily be trained by “Teach in” keypress.

There are 3 selectable operating modes:

Independent: In this mode, both paddles move in completely autarkic curves. There is no synchronization between the two axes. The number of vertices and the speed are independently selectable. The dynamic speed of both paddles can be adjusted due to separate set points.

Synchronal: In this mode both paddles move with the curve defined for the left paddle. Both axes are mutually fully synchronized that means, the number of vertices, as well as the speeds are identical to each other. Using adjustable set point, the offset between the two axes in the range of 0 and 180 degrees can be freely defined. The overall dynamic speed of both paddles can be adjusted due to the set point of the left paddle.

Batch Cutting: In this mode, both paddles move into completely autonomous curves. Both axes are synchronized to zero crossing towards each other. The number of vertices and the speed are independently selectable. From a defined position until curve beginning at 0 degrees the faster paddle is stopped, so that a common pass with both axes with 360degrees is possible. Both paddles can also be set dynamically by separate set points in overall speed.

Horn Glass Industries AG is committed to constant development and innovation in glass production technology.

By replacing the frequency drive of the chargers by a servo drive the new HORN charger is now able to improve the melting of the batch.

Thus making the HORN furnace once again energy efficient and more environmentally friendly. This is another tool to EcoFurbish® your furnace.

600450

600450

Add new comment