Date: 11 September 2017

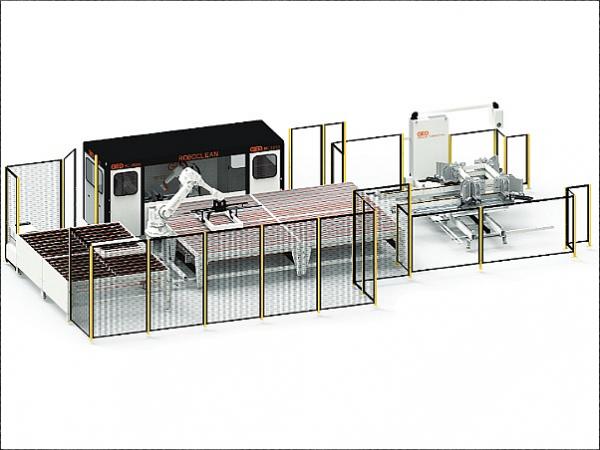

ROBOFLOW is offered in two versions, frame or sash flow-through systems that coordinate GED's 4 Point Welders to GED's RC-2000 Cleaners with the implementation of an integrated robotic handling station.

The system follows an integrated computerized schedule or bar code generated scheduling to orchestrate the movements and flow of multi-stack vinyl frames or sashes onto an x-y conveyor to the material handling robot.

The material handling robot, in conjunction with the x-y conveyor, work together to orchestrate movements of the vinyl assemblies into and out of the RC-2000 cleaner.

The robotic handling station turns the product around to clean all four sides of the product, as well as remove it and place it onto an automatic output conveyor that feeds the assembly or glazing lines.

The result is a compact vinyl weld and cleaning system that improves safety, increases quality and throughput, reduces labor and optimizes the efficiency of the operation.

Visitors to GED's Exhibit #3437 will also have the opportunity to see the world's first truly collaborative, industrial robot, YuMI ("You and Me, working together") assemble Rubik's Cube in a surprisingly short period of time, courtesy of ABB Robotics.

Daily demonstrations of GED’s new ROBOFLOW will be provided in Exhibit #3437 throughout GlassBuild America 2017.

As a part of GED’s complete line of glass and vinyl window fabrication equipment and software, ROBOFLOW is backed by the company’s leading training and support services.

600450

600450

Add new comment