Date: 5 April 2018

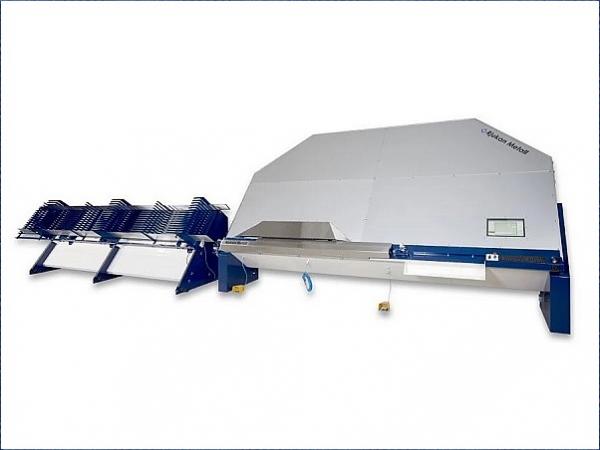

The MB950 bar bending machine – complete with AM 01 semi-automatic rack, allows us to bend aluminium, steel and warm-edge spacer bar every 28 seconds.

The machine optimises our sealed unit production through its innovative, universal head. This eliminates time-consuming tool changes and means Astraseal can bend an impressive 1,000 bars on a single nine-hour shift.

At Astraseal, we never settle. We are always looking at ways to better our performance and our overall service to ensure we can help our customers meet every demand with top quality products. Consistently investing in high-performance machinery is just one of the many ways we achieve this.

Our sealed unit manufacture is an important part of our business – currently producing over 3,000 sealed units every week. Investing in the latest technology means we can increase this number and therefore deliver an even faster service for our customers.

It’s also important in ensuring a high-quality finished product every time. Of course, accidents do sometimes happen on site and we can support our customers through our fast-track remake service – regardless of fault.

Completing Astraseal’s hat-trick of machinery investments is the intelligent DF502 desiccant filler. The DF502 brings ultimate precision to our operation, by automatically drilling the corner holes, filling the spacer bar with the specified ratio of desiccant and then sealing the openings ready for application.

With the competitiveness of the market, installers can’t afford to be going back to site replacing poor quality or failed units, investments like the bar bending machine and the desiccant filler mean we can keep delivering the exceptional levels of quality that our clients across the country have relied on for decades.

With one of the biggest portfolios in the industry, we’ve built a strong reputation for high-quality aluminium and uPVC products including windows, doors and conservatories. For over 30-years, operating from Wellingborough, Northamptonshire, Astraseal’s ethos has been to offer exceptional products with customer service that goes above and beyond.

600450

600450

Add new comment