Phosphorescent glass reveals the attraction of phosphorescent pigments, a material originally developed for security reasons and also used in the watch industry.

Brilliant colours and a new dimension of chromatic depth are evoked by the application of phosphorescent enamels on glass. Within the production process the colours are "burnt" on the surface of the glass, which guarantees the persistence of the intended design.

With the application of the phosphorescent pigment in the described manner the luminous power is not hampered. The "afterglow" pigments are not toxic and non radioactive.

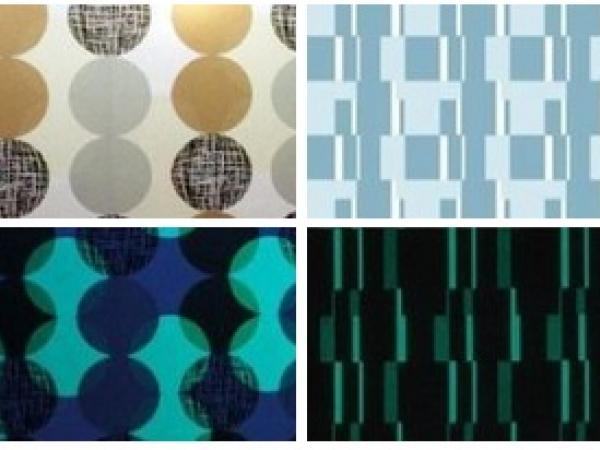

In the darkness the natural transparency of the pigment fosters a chromatic overlapping and mixture eventually appearing in ever changing green-yellowish illumination.

It offers various applications in interior and exterior for example as architectural glazing elements or other glass products. It allows as well to save energy coasts for lighting.

Phosphorescent glass ‘ecloon’ - is tempered safety glass with a special ceramic coating creating shining and glowing effects on glass. This effect of the coating can be self-illuminating, afterglowing or lighting. It allows as well to save energy coasts for lighting. phosphorescent glass ‘ecloon’ is available as insulated, laminated and monolithic glass.

.jpg)

.jpg)

Phosphorescent glass tiles "onda". The pattern is 2D in the light and 3D in the dark.

Elevator glazing - the moving cabin leaves a lucent trace, giving the facade a unique touch.

APPLICATION

This innovation in glass is predestined for individual accents in architecture.

Architecture: the phosphorescent glass allows to create „self-lighting“ glass façade, or can be used on façade glazing for printed on logos or designs. It could also be used for elevator glazing to get special lighting effects with the moving cabin.

Interior Design: the new glass coating works for interior wall cladding (glazing, glass tiles), glass stairs, doors, ceillings and furniture etc.

Security: using the coating in escape areas – doors, wall cladding etc.

Phosphorescent wallpaper

SELF–ILLUMINATING-EFFECT

By blacklighting or floodlight (wall washer) with invisible UV-black light 36W/73 Radium. Only the coated area is activated and appears to be a self-illuminating body.

Absolute uniform light intensity of approx. 70 cd/m2 are achieved at a horizontal distance of 50 cm from the glass. The vertical distance of the light source should also be 50 cm in order to visualise the unusually high brightness – also in external applications in urban areas.

AFTERGLOW-EFFECT

In absolute darkness (Interior) activation through daylight or artificial light is sufficient to achieve up to 10 hours of afterglow which can be seen by the human eye (visibility limit). In accordance with the requirements of DIN 67510 for phosphorescent glass.

In combination with other colours the illuminating pigment creates a 3-dimensional effect on glass (p.e. through double sided coating).

.jpeg)

Phosphorescent glass table "flora"

LIGHTING

The activation of the performance coating occurs ideally with UVA-Light in the spectral area of 350 – 390 nm. Practically no visible light is apparent in this area which is why it is called UV-Black light. UVA rays are subject to limits in order to avoid health risks! The measurement was therefore carried out using UVA lighting tubes – which do not possess any UVB rays. To intensify or to time the effect of e.g. logos or patterns, there could be in addition integrated lighting systems p.e. in the facade construction.

FUNCTION PRINCIPLE

Originally developed for security reasons zinc sulfide increasingly establishes itself within architecture, design and arts.

Dispersed zinc sulfide is mixed as pigment with the ceramic coating and fused into the glass surface at a temperature of approx. 600°C during the tempering process.

Zinc sulfide is known in other applications and is activated through UV-radiation. This European patented product from the RE group in Cologne is manufactured and distributed exclusively by ECKELT GLAS GmbH.

The product is covered by European patent (EP 027 02 213.6), from gruppe RE, Cologne, and is manufactured and distributed by Eckelt Glas GmbH.

.jpg)

Silke Warchold is head of "gruppe RE interior + product design", Office for Interior design, product design, product development based in Cologne/Germany. She is lecturer activity at the TU Eindhoven/Netherlands, Department Industrial Design and University of Applied Sciences Düsseldorf/Germany, Department Architecture and is the patent holder of "phosphorescent glass" - Patent EP 027 02 213.6

gruppe RE interior + product design

Volksgartenstrasse 23 - 50677

Germany

Tel: +49 - 177 - 7737201

E-mail: mail@gruppe-re.de

www.gruppe-re.de

© gruppe RE • www.gruppe-re.de

ECKELT GLAS GMBH • www.eckelt.at

Date: 1 July 2010

Phosphorescent glass, a material originally developed for safety reasons is now being used in architectural glazing, especially in interior and exterior decorating.

600450

600450

Silke Warchold

2010-07-01T13:00:00

Self illuminating architectural glazing elements

glassonweb.com