Date: 20 January 2017

SCHOTT has been awarded a contract for the production of mirror substrates for the secondary (M2) and tertiary mirrors (M3) of the European Extremely Large Telescope.

M2 will be the largest convex mirror ever produced. A second melting tank will soon go into operation to meet the sustained high demand for ZERODUR® glass-ceramic.

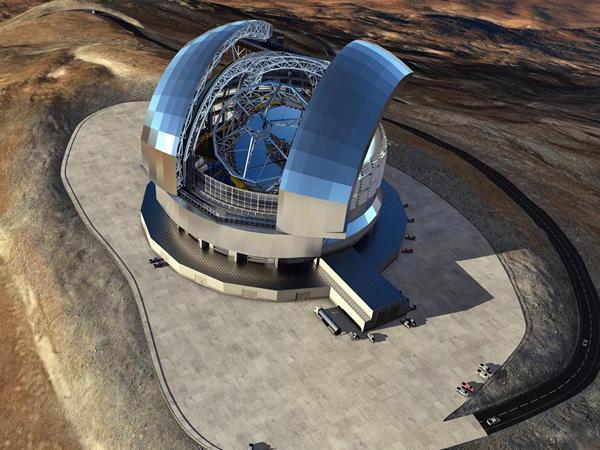

The largest optical telescope in the world – the European Extremely Large Telescope, or E-ELT for short – is currently being built on the Chilean mountain Cerro Armazones.

The giant telescope is based on a five-mirror design: a giant main mirror (M1) and four smaller mirrors (M2 to M5) as reflectors.

It is comprised of know-how from Germany: SCHOTT technology group was awarded today the contract to supply two additional mirror substrates.

After substrates for the segmented M4 mirror left the SCHOTT plant in Mainz last year, another order for ZERODUR® glass-ceramic is now following as part of the E-ELT project.

The special feature of ZERODUR® glass-ceramic as a mirror substrate is its extremely low thermal expansion coefficient.

This means that even in the case of large temperature fluctuations, the material does not expand. Even chemically, the material is very resistant and can be polished very well.

The actual mirror layer with its extremely smooth surface made of aluminum or silver is usually deposited with vapor shortly before the telescope is put into operation. The result is extremely sharp images for exploring unrivaled worlds.

In the E-ELT project of the European Southern Observatory (ESO), these features are especially effective because the design is ambitious: the 39.3 meter primary mirror, also called “Mirror 1” or “M1,” collects light from the night sky and reflects it on a smaller mirror, the M2, at four meters in diameter.

This in turn reflects the light to a reflector (M3) placed in the center of the M1. The task of this third mirror is to irradiate the light onto an adaptive optics (M4) placed above it, which changes its surface a thousand times a second and thus straightens the distorted starlight again.

“We are very pleased to be part of the groundbreaking E-ELT project. In order to continue to satisfy the sustained high demand for ZERODUR® glass-ceramic in the areas of IC/LCD lithography, aviation and metrology, we will be putting a second melting tank into operation at the main plant in Mainz shortly.

In addition, we have expanded the capacity of our CNC processing to grind the material in the two- and four-meter class by means of state-of-the-art CNC machines, which we will officially inaugurate shortly,” said Christoph Fark, Executive Vice President Advanced Optics at SCHOTT.

“The machines will help us to optimize our manufacturing capabilities even further and to meet tight tolerances for applications with the highest demands, such as the mirror substrates for the E-ELT. In total, we’ve invested a double-digit million figure in ZERODUR® production in order to secure and further expand our excellent market position for the future.”

Proven material – “Made in Germany”

The cast and the grind of the E-ELT mirror substrates will be carried out at SCHOTT headquarters in Mainz. The French company Reosc which specializes in the processing of ZERODUR® will take over polishing and coating. The mirror substrate of the M2 is to be produced and delivered by the end of 2018, and the M3 by July 2019.

SCHOTT recently launched a microsite (www.schott.com/e-elt) where interested people can find information around the E-ELT project. The content of the website will grow over the next months, providing facts and figures around the mega telescope and illuminating SCHOTT’s contribution.

Knowledge from research and development translates into other products

Since 1903, SCHOTT has been providing telescopic mirror substrates with larger dimensions, and since 1970, SCHOTT ZERODUR® has established itself as the de facto standard.

Accordingly, many well-known telescopes have been operating reliably for decades with ZERODUR® mirror substrates. This includes, for example, the ESO’s Very Large Telescope in Chile with four mirror substrates, each measuring 8.2 meters in diameter.

SCHOTT has already translated the technological expertise of ZERODUR® into other fields of application. The formula of the high-quality glass-ceramic cooktop panel SCHOTT CERAN® is based on the material that was originally researched and developed for astronomy. SCHOTT ROBAX® is yet another good example.

The transparent glass-ceramic for fireplaces convincingly withstands great heat for a high degree of fireplace safety in the more than 75 million fireplaces that have been sold over the last 35 years.

600450

600450

Add new comment