Date: 13 March 2017

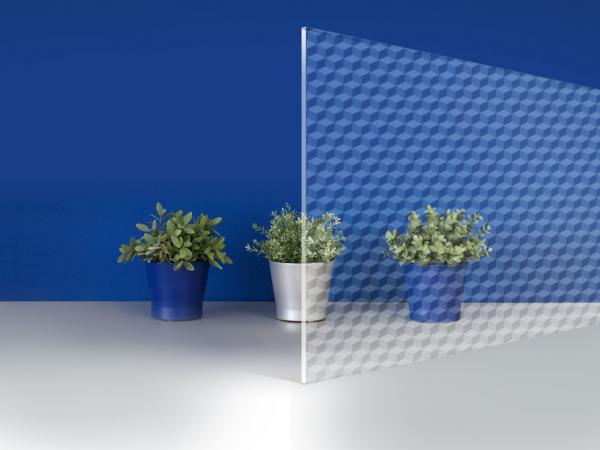

When people think of the sandblasting technique it suddenly comes to mind decorative glass, especially deep engraving works. Sandblasting certainly finds application in decorative glass works, such as engraved designs, shower boxes or glass balustrades, but there’s no enough knowledge about other possible applications in the glass industry.

Sandblasted glass is actually often used for double glazing and double layer glasses, when a “hazy appearance” is required, and represents a perfect base for painted glass, as the sandblasted surface, rough and porous, absorbs the paint much more than a smooth one.

Sandlblasting also helps the glassworks in significantly reducing scraps, as the glass panels that present surface defects such as scratches or marks can be fully sandblasted and used when a supply contract includes frosted glass items.

That’s why the purchase of a sandblasting machine still represents a smart choice, considered the limited extent of the investment and the low process costs. Fratelli Pezza srl., lcated in the north of Italy, is worldwide leader in the manufacture of sandblasting and marking equipments for flat glass since 1970.

The automatic models of the MISTRAL EV and ZEPHIR series are the most reliable and cost effective sandblasters available on the market and represent an optimal investment for all glassworks.

600450

600450

Add new comment