Date: 15 March 2023

Efficient logistics allows customers to maximize production and machines manufacturers should be proactive and contribute to facilitate the organization by enhancing automation.

In glass lamination, some jobs like loading and positioning of glass into laminating bags are usually manual demanding time and strength, and in case of heavy glass combinations should be handled.

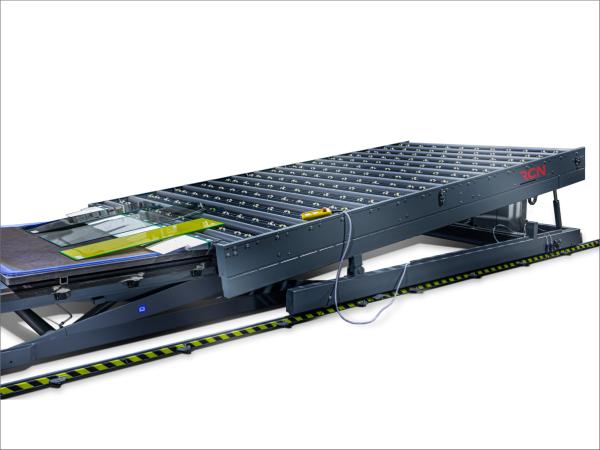

In this view, RCN SOLUTIONS has developed a semi-automatic conveyor for glass loading prior to lamination. This system, recently and successfully installed in Japan, grants the automatic loading and positioning of the glass directly into the laminating bag. The conveyor, equipped with rollers, first slides over the lifting platform, lifts and releases glass directly into the laminating bag while moving back to the original position.

Ideal for big size machines and production volumes, particularly when jumbo and oversize laminations are becoming part of normal production for most glazier shops, CNV can be manufactured according to customers’ requirements.

RCN SOLUTIONS offers devices and machines to maximize customers’ manufacturing time and reduce the number of manual operations.

The video shows how the conveyor works.

600450

600450

This system, recently and successfully installed in Japan, grants the automatic loading and positioning of the glass directly into the laminating bag.