Date: 17 February 2017

The demand for Heat Soaking has greatly increased within all sectors over the years, a process more often associated with the architectural glass market this is now used heavily with all other sectors.

This process dramatically reduces the risk of spontaneous failure of toughened glass, caused by Nickel Sulphide (NiS) inclusions. These inclusions are a natural occurrence which happens during the manufacturing stage of standard float glass.

Once the float glass is toughened, a process which involves heating the glass and rapidly cooling it, the NiS heats up but does not cool and remains in its ‘high temperature state’.

Over a period, as the NiS cools the physical mass or volume of the NiS increases. This increase in mass is what then puts internal pressure on the glass and can then can cause spontaneous breakage.

Despite massive investment by the float glass manufactures in both R&D and technology to prevent these NiS inclusions they cannot be prevented completely. However one way to reduce spontaneous failures is to subject the glass to an additional heat soaking process.

Heat soaking is a destructive process where the glass is heated up and left at a high temperature for a period of time.

This temperature is enough to allow expansion of the glass (simulating real life exposure to solar heat) but low enough to allow the NiS to return to its cool mass. Thus, causing the panel to fail during this heat soaking rather than on site after a period of time.

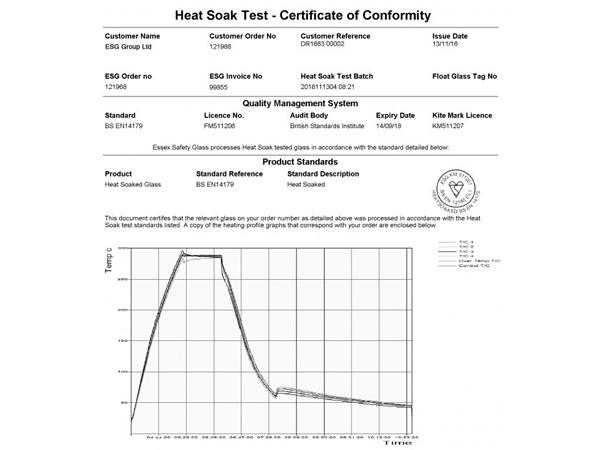

In todays ‘Health and Safety’ conscious environment, main contractors and architects are increasingly asking for records to show the cycle that all heat soaked glass has been subjected to.

In an effort to make this reporting as easy as possible, ESG Group have developed an industry leading procedure that allows a report to be automatically generated and sent to the customer for every piece of heat soaked glass, showing the graph of the heat soak cycle specific to that piece of glass.

In an extension to their current ISO 9001 procedures, where every piece of glass is barcoded and tracked through every stage of production, ESG are now able to scan each piece of glass into the heat soaker and at the end of the cycle a report is produced showing a time/heat graph of the heat soak cycle.

This graph is then allocated to the barcode of each piece of glass that was in the heat soaker. Upon invoice an automatically generated Certificate of Conformity will be produced and emailed out with an embedded image of the Heat Soak graph detailing the time, date and the TAG ID of the glass used to produce the order.

These reports are also digitally stored for easy access should they be requested at a later date.

ESG are the only glass processor in the UK to be using such a transparent and easily communicated heat soaking report.

600450

600450

Add new comment