Date: 26 January 2016

The frit inks are also well-suited to other severe outdoor environments where organic inks may degrade and impede performance.Components with frit ink pass through a tempering oven where temperatures are highly elevated and the graphics essentially become part of the glass itself.The graphics are then scratch and abrasion resistant, and retain their original appearance throughout the life of the glass. Once applied, the frit will meet operating temperatures similar to the glass substrate itself.

Frit ink is available in black and white as standard, with custom Pantone match colors available. The minimum glass thickness for applying frit is 3mm (0.118”). Feature resolution can be as fine as 0.305mm (0.012”).

According to Jacky Vel, Vice President of Sales and Marketing, “Screen printing with ceramic frit ink offers our customers many benefits. Primarily, moisture, oil, soaps, chemicals and detergents will not impact the screen print integrity, a must in many harsh or high use environments.”

.jpg)

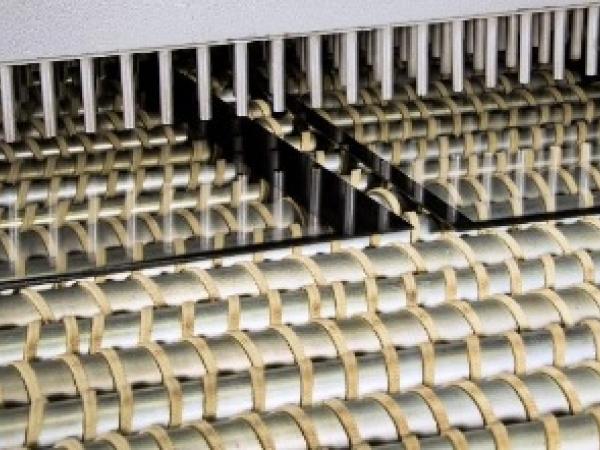

Frit ink screen printed glass undergoing heat tempering

Abrisa Technologies is a recognized global supplier of high quality, fabricated glass components, optical thin film coatings, and custom glass solutions for a wide variety of industries. From our US based Abrisa Industrial Glass fabrication facility in Santa Paula, CA and our ZC&R Coatings for Optics division in Torrance, CA we serve diverse industries such as microelectronics and displays, semiconductor, military, automotive, aerospace, medical, biomedical and scientific R&D. We provide custom specialty flat glass and coating products for applications such as: flat panel display, touch and gesture recognition; visible to IR imaging and surveillance; entertainment, indoor and outdoor lighting; advanced instrumentation; and photonics.

Contact us at www.abrisatechnologies.com for more information and to request a quotation.

600450

600450

Add new comment