Date: 6 July 2016

This last machine is part of our wide range of washing machines: Lattuada is not only edging and bevelling!Our product range counts 15 models, from the most basic version with manual speed change and thickness up to 15mm, to the most important one able to process glasses up to 3,300mm, thicknesses up to 40 mm and weights up to 800Kg.

A lot of options are available, such as the possibility to have belts instead of the standard rolls, in order to help the operator while loading/unloading small or rounded/shaped glasses; motorized adjustment both of the glass thickness and the conveyors, to guarantee a high washing quality on each thickness; black panel with inspection lamps for a better check of the glass cleaning degree; sensors for a higher safety and to manage various energy saving functions and many more.

All our washing machines can be integrated with vertical CNC machines as well as included in our edging and bevelling lines, also thanks to the possibility to have the work surface at the same height. On request it is possible to manage thickness and speed adjustment ‘in-line’.

Furthermore all our machines can be integrated with:

- robots installed between two or more grinders (most common application is with two machines and one robot).

- ‘loop’ systems that can be installed on a single machine, to automate and speed up the work cycle, thus obtaining increased optimization of productivity: the easiest, most flexible and simple solution. The system can load the glasses, bring them from the outlet conveyor to the inlet conveyor rotating them 90°. Also available with automatic load/unload from harp racks management.

- piece rotating devices for complete grinding lines.

- complete vertical lines of harp racks, edging, washing, drilling and milling machines.

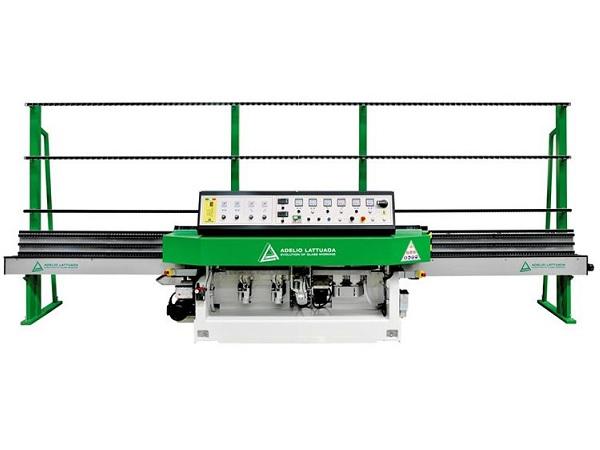

Another model we would like to put emphasis on is our 13-wheel edging machine, which can carry a total weight of 2,200Kg, process thicknesses up to 100mm and sizes up to 12 x 3.21m – the only one able to vertically grind such a great thickness.

On the outlet conveyor of the machine will be fitted the OT 300 motorized washing machine to completely clean and dry the processed edge of the glass sheets. It automatically position itself according to the glass thickness set on the machine.

600450

600450

Add new comment