Date: 19 March 2024

The provided example highlights the productivity gains achievable by integrating a line of double edgers for flat edges (two machines connected by a transfer table), a loader and unloader with a turning table, and a 4-head drilling center. This line, recently delivered to a customer in Brazil, showcases how incorporating 'side' processes enables the creation of perfectly optimized and fully automatic cycles.

What are the benefits of a full-cycle combined glass processing line?

Generally, it leads to increased productivity, attributable to reduced downtime and enhanced by greater precision, automation, and the simplification of the operator's role, who increasingly becomes an enabler and controller.

Specifically, the loader and unloader facilitate quick and straightforward positioning and unloading of sheets, improving precision and automatically recalibrating the machine based on their size. The drilling center completes the processing work, resulting in a finished plate at the cycle's end.

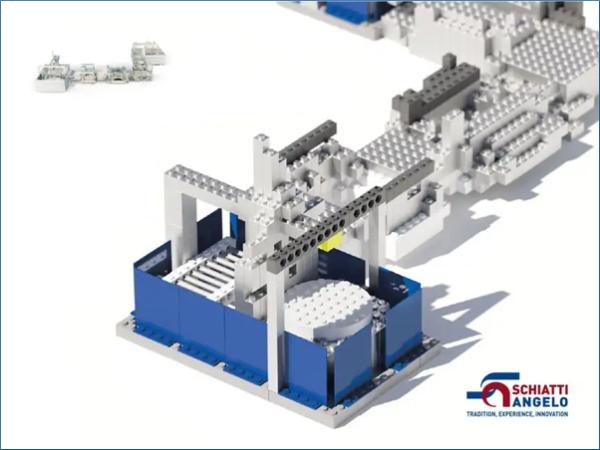

Efficiency Grows Brick by Brick

Choosing to depict our machines with the universally recognized 'build everything' bricks aims to convey how, with machines designed for both standalone and combined system operation, setting up work lines is incredibly simple and modular. Needs are assessed, solutions devised, and objectives met.

We are always ready to hear your needs and collaboratively determine which solutions, whether simple or complex, best suit them.

600450

600450

Add new comment