Date: 20 January 2017

With a lambda value of just 0.18 W/m·K, it permits a better Uf value when retaining the same frame installation depth, or a smaller installation depth with the same Uf value.

Large areas of glass, slim frames, high energy efficiency: these features, desired by building owners and architects, can be achieved particularly with aluminium frames – assuming there is efficient thermal separation. Ensinger, inventor of insulating bars between outer and inner shells of metal frames, is now going one step further.

“We have succeeded in lowering the thermal conduction capacity of the insulating profile by a further 40 percent”, explains Jan Danger, Head of the Construction Products Division at Ensinger, the plastics specialist. “With the lambda-optimised insulbar LO, it is possible to produce even more delicate frames that meet the highest standards when it comes to the insulating properties.”

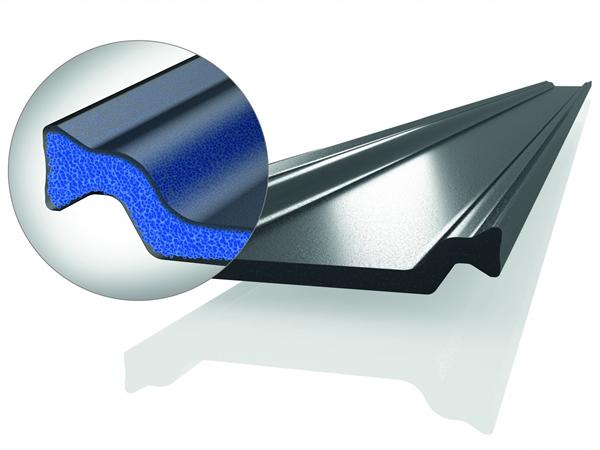

With a thermal conduction coefficient (λ) of just 0.18 W/m·K, the new insulating profile LO has the usual smooth, compact exterior. The key to its even greater insulating efficiency is its porous core: the glass fibre reinforced polymer blend (PA 66 and PPE) contains microscopically small, closed cavities.

This special structure is patented by Ensinger. The insulating properties are improved and the insulating bar is also lighter than a solid profile. The requirements of DIN EN 14024 regarding transverse tensile strength and shear strength are fulfilled (test report by the ift Rosenheim).

insulbar LO is precisely moulded and available in the conventional geometries as well as in individual designs and styles.

The variant LEF for example, assisted by a Low-e film on the flags of the profile, reduces energy losses through heat radiation to a minimum. Capable of being processed in the normal way, insulbar LO also permits anodisation and powder coating in the finished assembly.

600450

600450

Add new comment