Date: 10 February 2016

It will be displaying profile storage systems and an enhanced door and element storage frame, alongside a Renault Master, specially converted for the transport of large panels.

Storage system“Our profile storage systems will enable us to demonstrate how you can increase existing space capacity by up to 50 per cent”, explained HEGLA Product Manager Mark Stoschek. Closely set storage racking, mounted on rails, makes optimum use of space.

There are no more operating aisles between rows of pallets, as the storage system requires just a single opening.

The racks can be motor-driven or operated by crank handle, and are moved sideways to allow direct access. Time-consuming pallet restacking is a thing of the past.

.jpg)

Product unit: Paternoster System

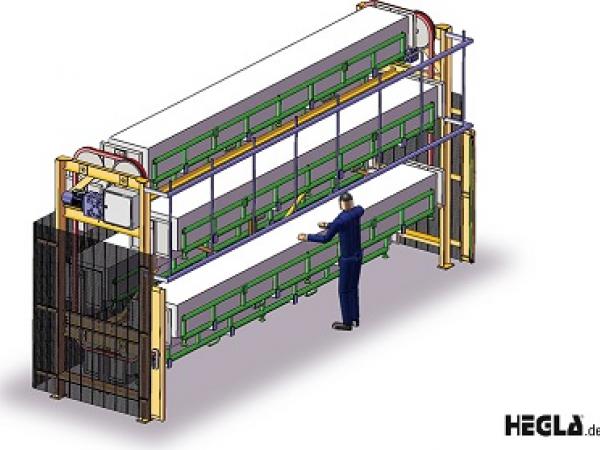

HEGLA will also be presenting a paternoster system - its latest innovation in this sector.

Managing Director Bernhard Hötger is confident that “this is an ideal solution for companies with limited floor space for profile materials but sufficient ceiling height”.

With its six or more compartments, HEGLA believes it is perfectly suited for supplying profiles in door and window production, and spacers for the manufacturing of insulating glass.

The profiles can be removed at the same height as the production line for operator-friendly handling. The vertical storage system moves up and down, guaranteeing much shorter handling times than a conventional system.

TEL door and element storage frame for space-saving storage and dispatch preparation

The new TEL door and element storage module and matching RF6 transfer trolley also aim for optimised, shorter procedures. The RF6 is equipped with six adjustable compartments and a user-friendly roller mechanism, making the trolley ideal for transporting finished special elements from the production line to the shipping department.

.jpg)

The new TEL door and element storage system is perfectly adapted to the RF6, ensuring an interlinked process. The elements transported to the shipping department can be pushed out of the transfer trolley directly into the storage module with the aid of dovetailed roller mechanisms. Protective brush strips at the side prevent scratches. The elements are stored in minimum space. HEGLA offers compartments in different widths, customised to the customer’s requirements, for example to fit doors with a roller shutter box.

Renault Master with Glass Rack

For those looking for a suitable solution when it comes to delivering construction elements or panels, HEGLA offers its stand visitors the chance to have a closer look at a Renault Master with a glass rack. Protective cushioning and tension rods ensure that the load is safely secured and easily transported to the customer. The standard rack is equipped with two fixing bar for extra safety. The basic version also includes an integrated climbing aid for easy access to the roof or the optional roof rack. An optional ladder roller rounds off conversion to an industry vehicle, just as an integrated tool cabinet system turns the vehicle into a mobile workshop. Everything is in its place, conveying a professional image to customers. Hans-Peter Löhner, Managing Director of HEGLA Fahrzeugbau, the Group’s vehicle centre with three sites in Germany, is looking forward to Fensterbau. “Not only will we be meeting new customers in Nuremberg, we’ll also have the opportunity to see old acquaintances and friends that we’ve perhaps not seen since the last trade fair”, said Löhner. “As a specialist supplier, it is important to discuss upcoming trends with professionals, so that we can continue to offer suitable solutions.”

.jpg)

Visit us at Stand 103/Hall 3a.

600450

600450

Add new comment